ShengjiPetro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement and test equipment, which can meet the requirements of product design, development, production and service and has the only multiphase flow laboratory for Sinopec. The main products are single-screw and twin-screw oil-gas mixed pump, MFM2000 series multiphase flowmeter, LPT multiphase metering device, HPT multiphase metering device, on-line water-bearing analyzer and single-well gas-liquid flowmeter device. Vortex Separation Multiphase Flowmeters with the following characteristics:

Integrated design.

CMF measurement technology.

The automatic measurement process is controlled by the computer.

Equipped with a well washing fluid pipeline.

The test process can be equipped with RTU.

Equipped with a casing gas metering pipeline.

ShengjiPetro Vortex Separation Multiphase flowmeters are mainly used for single well measurement and testing in oil fields. The product can cover the water content and gas content of 0~100% without separating the three phases of oil, gas and water. Online, real-time measurement and monitoring is an alternative to traditional test separators. The standard multiphase flowmeter can be permanently installed at the wellhead or metering station to achieve continuous monitoring of production wells and production metering. Due to its small size, light weight, and ease of movement, it can also be used to provide mobile production testing, exploration testing, and evaluation testing services for oilfield users.

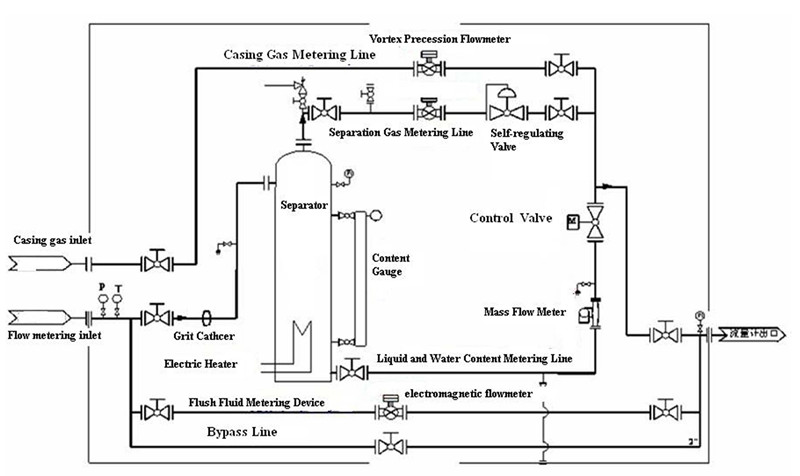

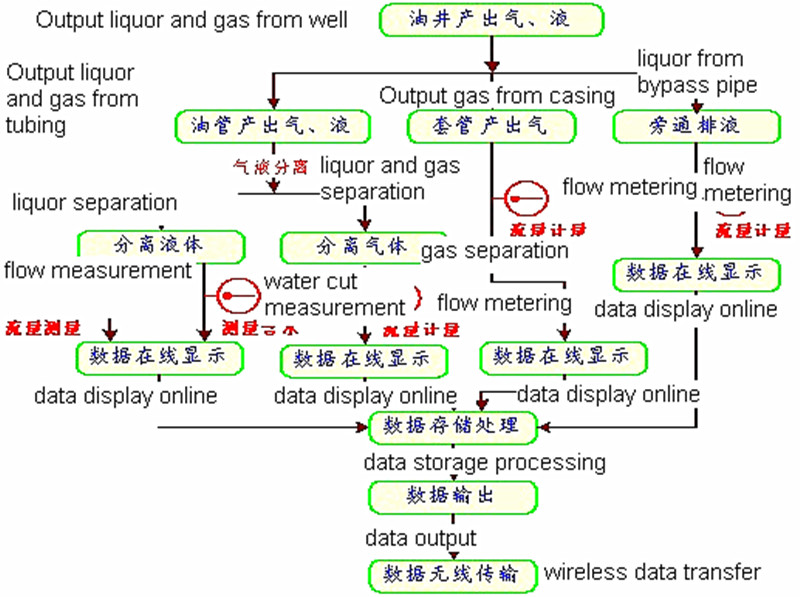

Based on the principle of separation and measurement, the device uses the vertical swirling and horizontal sedimentation technology independently developed by the company to completely separate the gas and liquid of the oil well and measure it separately. The switch of electrical gate valve in gas-liquid pipeline can control gas and liquid discharge through control chip based on the liquid level inside the separator.

External liquid (gas and liquid) first pass through multiport valve, measure the liquid pipeline, choose relevant metering process (time-sharing automatic selection or manual selection). Gas and liquid flow into the device, first entering into desander (to adapt the application of sand-content crude oil, there is the matched desander in the system, which can clean the sand periodically), heat-exchanger, and then come to vertical two-phase separator, make most gas separation, enter into horizontal separator, make gas-content liquid separation, flow out the separated gas and liquid through different pipelines, there are metering device on the pipelines to measure the gas and liquid ( there are an area for liquid accumulation in the separator to adapt low yield and discontinuous liquid).

When accumulating liquid in the separator, close the liquid-way valve, open gas-way valve, vortex precession flowmeter measures the gas; when flowing out the liquid from the separator, open the liquid-way valve, close gas-way valve, the mass flow meter measure the liquid( there are self-operated regulator in the gas-way, can adjust the gas flow speed and discharge the liquid smoothly.)

There are magnetic flap liquid indicator and differential pressure type liquid indicator through which can observe the liquid level in the separator.

Measurement process control, data collection and processing are finished automatically through computer. The result is sent to the computer by a piece of data line, real time monitoring test process and output the test report according to client requirements.

Shengji Petroleum Pumping Unit Manufacturing Plant is one of the main branches of Shengji Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales and service of pumping units. The factory has 235 employees, more than 130 sets of various large and medium-sized mechanical processing equipment, fixed assets of 12 million yuan, annual output of 1,200 pumping units, and annual sales income of 200 million yuan.

There are 4 senior engineers, 12 intermediate engineers, 7 assistant engineers, 4 senior technicians and 12 technicians in the pumping unit. Intermediate and senior workers account for more than 90% of all workers. The superb technical level of employees provides a technical guarantee for the production of high-quality pumping units.