ShengjiPetro is the No. 1 thermal recovery solution supplier in China with 20 years of experience. ShengjiPetro can provide customers with a complete set of thermal recovery equipment from surface steam injection boilers to underground thermal recovery downhole pumps. We can provide customers with the design, development, production, installation, commissioning, and stem injection services. ShengjiPetro can produce the following auxiliary equipment for thermal recovery:

Steam Injection Boiler

Water Treatment Device

Ground Steam Injection Line

Series Thermal Recovery Wellhead

Vaccum Insluation Tubing & Casing

Thermal Recovery Packer

Integrated Injection and Production Sucker Rod Pump

In the heavy oil recovery, the pressure of some oil wells is high. The working pressure of subcritical steam injection generator cannot meet the needs of thermal recovery in high pressure heavy oil wells. In view of this situation, ShengjiPetro developed a new oilfield supercritical steam injection boiler. The rated pressure of gas injection boiler is higher than the critical pressure (22.15mpa) and therated temperature is higher than the critical temperature (374.3℃).

https://youtu.be/HYm59Zb3QCg

Characteristics of Supercritical Working Medium

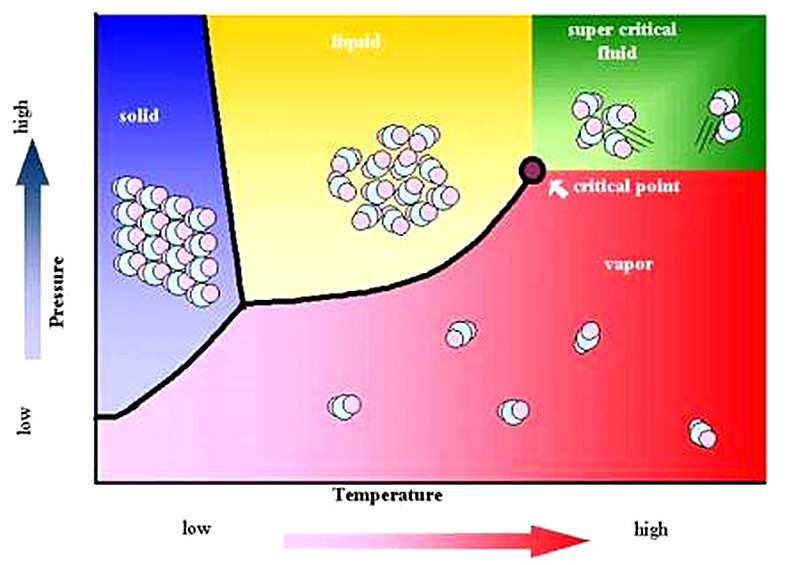

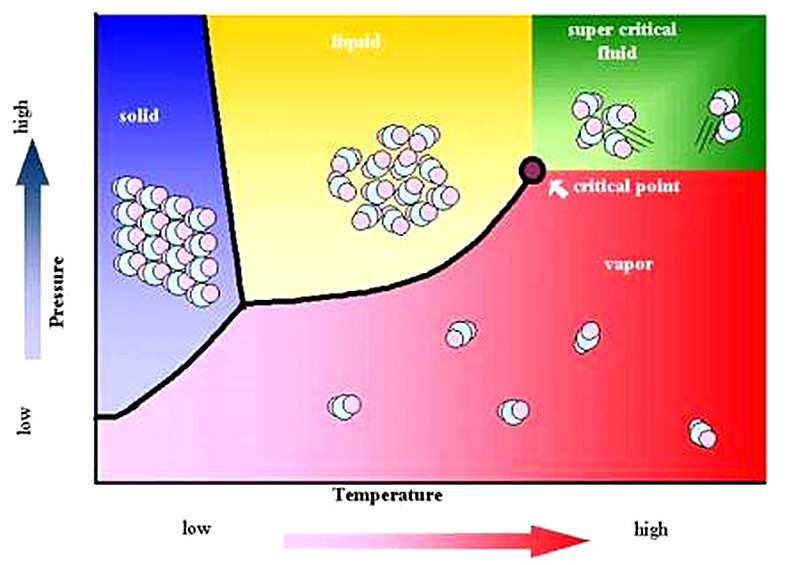

The critical state is the limit thermodynamic state of the equilibrium coexistence of gas and liquid phases of a substance. In this state, the thermal state parameters of saturated liquid and saturated vapor are the same, and the interface between gas and liquid disappears, so there is no surface tension and the latent heat of gasification is zero.

With the increase of pressure, the saturation temperature of water increases accordingly and the latent heat of vaporization decreases accordingly. In 21 MPa EOR steam boiler, if the dryness of steam is 80%, the average enthalpy is 2247.91kj/kg and the saturation temperature is 369.83 C. When the pressure reaches the critical pressure, if the steam temperature is controlled to operate at 374 C, the average enthalpy is only 1 821.33kj/kg, which means that when the pressure exceeds the critical pressure, the heat required for the working medium to rise temperature is much less than in the subcritical state.(The wall temperature of the furnace tube will also rise rapidly, which will easily lead to deterioration of heat transfer).

Steam quality measurement on an oilfield steam generator

Technical Difficulties of Supercritical Oilfield Steam Injection Boiler

The rated pressure of the Supercritical Oilfield steam generator exceeds the critical pressure (22.15mpa), and the temperature of the supercritical steam injection boiler exceeds the critical temperature (374.3 ℃), which makes the pressure and temperature of the steam injection boiler run higher, so the biggest difficulty is to keep the oilfield steam generator running safely.

The biggest safety accident of oilfield indirect steam generator is tube burst, and the cause of tube burst is heat transfer deterioration. As long as the occurrence of heat transfer deterioration is avoided, the operation safety of boiler is basically guaranteed.

Supercritical Oilfield Steam Injection Boiler Introduction

The working principle of supercritical Oilfield steam injection boiler is different from that of one-through steam generator under sub-critical pressure. The flow pattern of water-steam system has changed fundamentally. Working medium is a single-phase medium. There is no boiling state when both vapors and liquids are identical, and only two single-phase fluids are changed. We have carried out the following three key design projects.

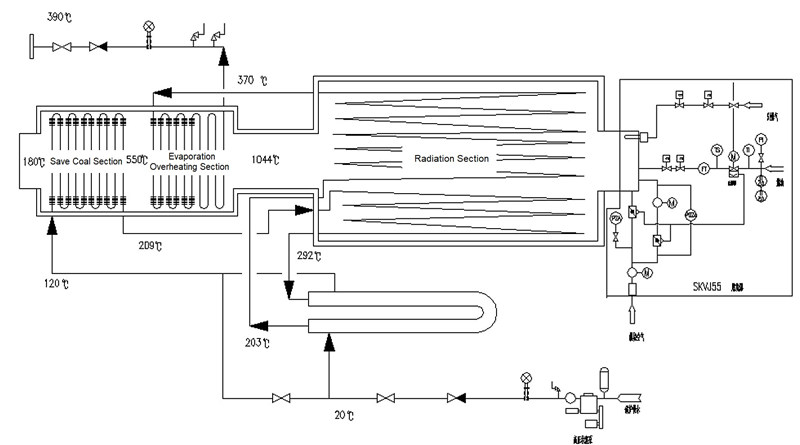

1).Move the heat exchange zone near the critical point prone to heat transfer crisis from radiation section to convection section in steam-water process.

In the design of supercritical oilfield steam generator, the heat exchange conditions near the critical point are complicated and it is impossible to accurately calculate the heat exchange coefficient and wall temperature. Therefore, in the design of boilers, it is necessary to avoid arranging this section in the area of maximum heat load Q (i.e. the center of flame).After checking calculation, it can be seen that heat transfer deterioration may occur in radiation section under low load, and heat transfer deterioration will not occur in convection section because maximum heat load is much lower than radiation section.(Radiation section q=92kw/m2, convection section q=70kw/m2).

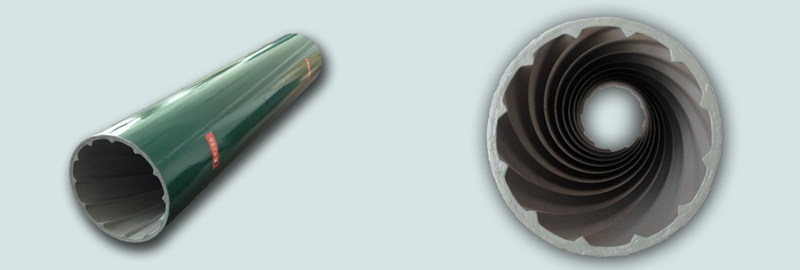

2).Internal threaded tube is used in both radiation and convection high temperature zones.

12Cr1MoVG internal threaded boiler tube is used in both high temperature parts of radiation section and convection section. The temperature resistance can reach 580 C and the high temperature performance is good. Its special structure can also effectively prevent the deterioration of heat transfer. Its main functions for preventing or delaying deterioration of heat transfer are:

(a) strong rotating steam flow formed by working fluid under the action of internal threads, which causes droplets to settle on the pipe wall;

(b) heat resistance of boundary layer is reduced, heat transfer is strengthened and wall temperature is reduced due to strong rotation of steam flow;

(c) liquid film in internal threaded groove is not easily carried by central steam flow;

(d) surface area of pipe is increased; Reduce heat load on inner wall.

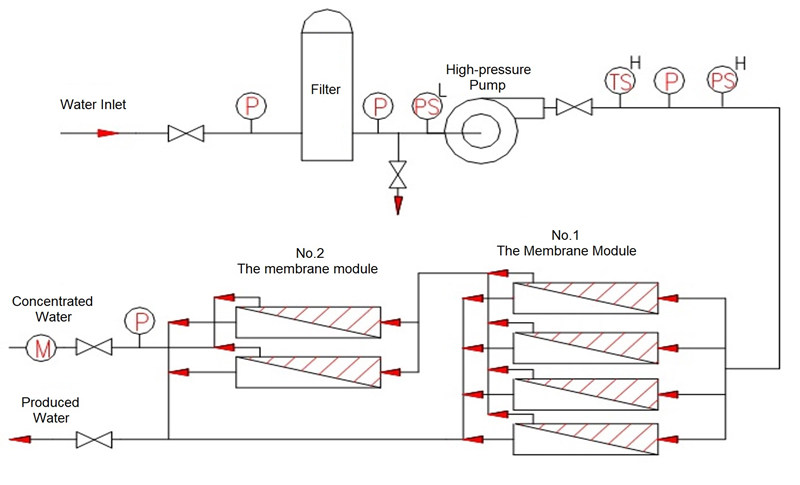

3). Reverse Osmosis + EDI + Membrane Deaeration Process is adopted

Supercritical oilfield steam generator is different from the original subcritical Oilfield steam generator because of its water vapor system characteristics, so the supporting water treatment equipment should not only consider the removal of hard and oxygen, but also must consider the removal of salt in water, so as to ensure the safe use of the boiler.

4).Targeted OTSG Automatic Control System

In order to ensure the safe operation of the supercritical steam injection boiler, the automatic control system of the boiler is optimized

a). Set up multiple alarm points and shutdown points to ensure safe operation of the boiler

When the boiler has high steam pressure, high steam temperature, high exhaust gas temperature, high pipe wall temperature (measuring 2 points), burner throat temperature is high, primary air pressure is low, secondary air pressure is low, inlet water pressure is low, fuel oil temperature is low, plunger pump lubricating oil pressure is low, power supply failure, flame failure, convection inlet temperature overrun, low feed water flow and other phenomena will automatically alarm.

b). Good hardware guarantee ensures the accurate operation of the automatic control system.

PLC host adopts high-end CS1 series products of OMRON company, which not only has high reliability and supports complex mathematical calculation, but also has powerful network communication management function, which can be easily connected with upper computer. It is equipped with high-precision 8-channel A / D module and D / a module to ensure the accuracy of each variable detection result;

Supercritical Oilfield Steam Injection Boiler Technical Parameters

1). Rated evaporation:9.2 t/h

2). Rated steam pressure:26 MPa

3). Rated steam temperature:390℃

4). Rated thermal efficiency:>90%

5). Load adjustment:70%-100%

6). Fuel: Oil and Gas Dual Use

7). Control mode: PLC + touch screen + industrial computer

8). Loading mode: Trailer

Shengji Petroleum Pumping Unit Manufacturing Plant is one of the main branches of Shengji Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales and service of pumping units. The factory has 235 employees, more than 130 sets of various large and medium-sized mechanical processing equipment, fixed assets of 12 million yuan, annual output of 1,200 pumping units, and annual sales income of 200 million yuan.

There are 4 senior engineers, 12 intermediate engineers, 7 assistant engineers, 4 senior technicians and 12 technicians in the pumping unit. Intermediate and senior workers account for more than 90% of all workers. The superb technical level of employees provides a technical guarantee for the production of high-quality pumping units.