ShengjiPetro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement and test equipment, which can meet the requirements of product design, development, production and service and has the only multiphase flow laboratory for Sinopec. The main products are single-screw and twin-screw oil-gas mixed pump, MFM2000 series multiphase flowmeter, LPT multiphase metering device, HPT multiphase metering device, on-line water-bearing analyzer and single-well gas-liquid flowmeter device. Double Separation Weighting flow Metering Device is a kind of MFM2000 series multiphase flowmeter with the following characteristics:

Alternate work of double tanks, achieves continuous metering.

It adopts integrated design, compact structure and skid mounted structure, so can be used for mobile or fixed equipment.

It can be applied to the measurement of foam crude oil and some heavy oil wells.

The entire measurement process is automatically controlled by the computer.

The flow metering device can be equipped with RTU and other equipment, to realize remote data transmission and remote monitoring.

For the complex conditions in Venezuela MPE3 oilfield including high viscosity oil, high gas content oil and foamy crude oil, ShengjiPetro had designed a brand-new solution for multiphase flow meter. This solution uses dual splitter, weight measurement method and built-in high efficiency cyclone separating device to engage the meter has the characteristic of wide adaption of measurement range, high accuracy, wide range, operation stability. The double separation weighting flow metering device has passed the prototype test and appraisal of the new product of Shandong Institute of Metrology and Qualification, and its main performance index has reached or exceeded that of foreign similar products. The product has also passed the national certification of Venezuela and can be used in all OPEC organizations.

The modified device has the following characteristics: double tanks work alternately to achieve continuous measurement; adopt an integrated design, compact structure, skid-mounted structure, can be used for mobile or fixed equipment; the entire measurement process is automatically controlled by the computer; the measurement device can be equipped with RTU and other equipment, to achieve remote data transmission and remote monitoring.

https://youtu.be/CzpuejdGTK0

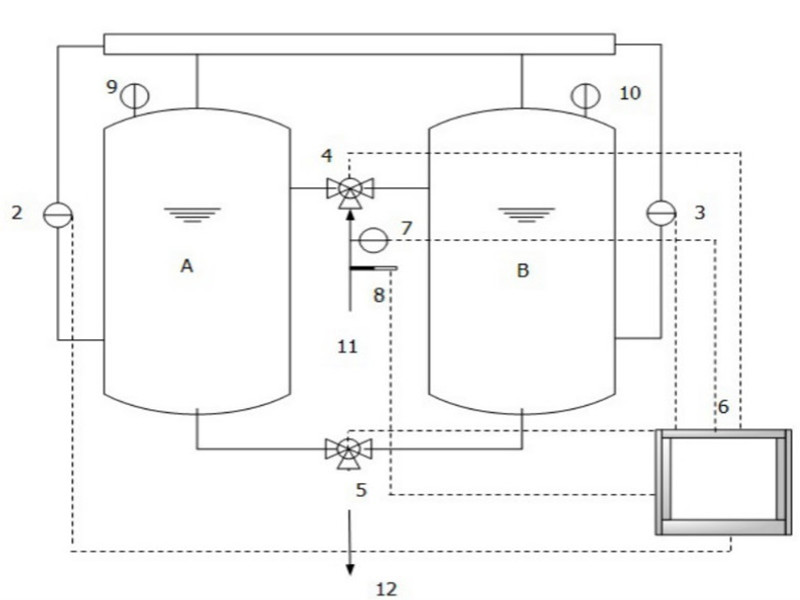

Structure Figure

A.B. Metering separator

2.3. Differential pressure transducer

9.10. Needle type manometers

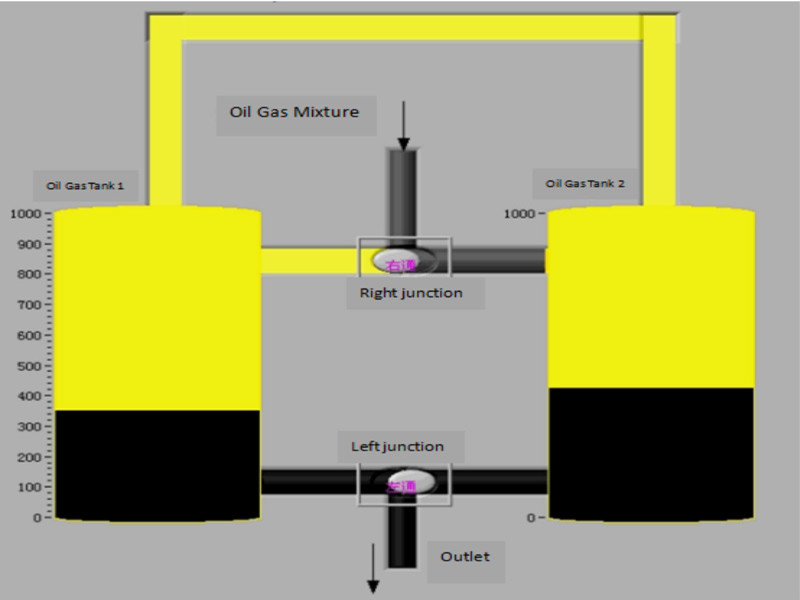

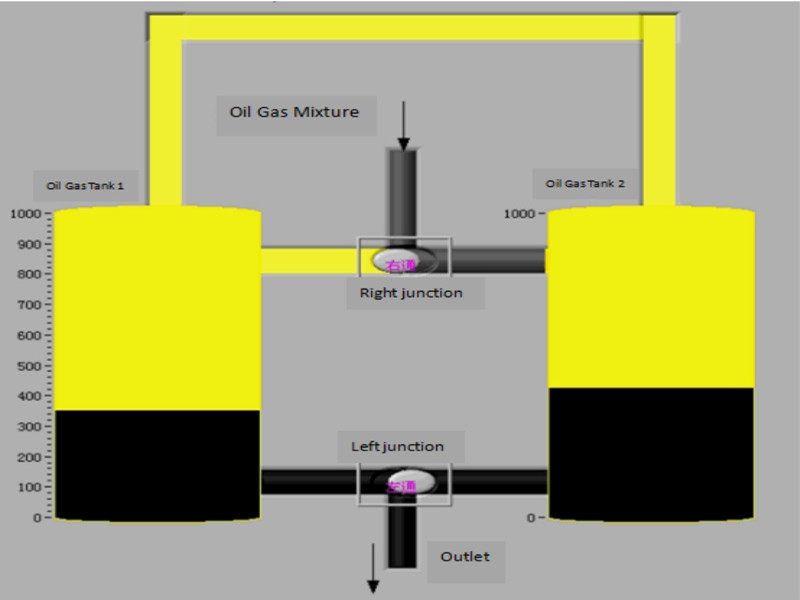

Oil Gas Tank Liquid Level Dynamic

(Note: black stands for the liquid, yellow for the gas, grey for oil and gas mixture)

While the import three-way valve opened for the left separator, export three-way valve opened for right separator. Then liquid level of left separator started to increase. When it reached to setting position, ΔP would be measured.

ΔP=mg/S

M is the mass of liquid column in the separator, g is acceleration of gravity, S is sectional area of separator. The mass of liquid column in the separator can be calculated by this formula and also obtain the flow of well from the change of the mass of liquid column. Control system controls alternate measurement of left and right separator, thus implement continuous measurement of well. After the measurement, intelligent control system is able to calculate the run of oil in the setting time to convert to daily oil production.

Double tank operation,when liquid flows in one tank, the air pressure pushes the liquid in another tank. System is airtight expect access channel. Therefore, under the airtight condition, the reduction of liquid accumulated value of double tank is the gas increment of airtight system. According to the change of tank sectional area and liquid level, the gas flow under current pressure and temperature is able to calculate. The gas flow under stander condition can be converted by gas equation.

| Measurement range | Gas measurement range

| 0~30000 Nm3 /d |

| Liquid measurement range | 0~1500m3/d | |

| Measurement accuracy | Gas flow | ±5.0% |

| Liquid flow | ±2.0%(0-400m3/d) ±3.0%(400-1500m3/d) | |

| Nominal pressure | 2.5 Mpa(350psi) | |

| Working temperature | 5-80℃ | |

| Power supply | AC480V 60Hz | |

| Explosion proof class | Exd II BT4 | |

| Signal output | Data remote transmission(RS485, modbus, Ethernet) | |

Advantages

1). In view of the defects of large error of heavy oil and foam oil by the conventional volume method, ShengjiPetro company designed and developed a dual-separation weighing measurement device. The modified device has the following characteristics: double tanks work alternately to achieve continuous measurement; adopt an integrated design, compact structure, skid-mounted structure, can be used for mobile or fixed equipment; the entire measurement process is automatically controlled by the computer; the measurement device can be equipped with RTU and other equipment , to achieve remote data transmission and remote monitoring.

2). The main advantage of multiphase flowmeter is that it doesn't need complete phase separation for the measured oil gas water mixture, the equipment realizes modular design, skid production, simple on-site installation process, compact structure and small space occupation; the measurement range is wide, which can be used for the measurement of individual oil wells, and also for the overall measurement and evaluation of a certain block in the oilfield. At the same time, the measurement process is real-time and continuous measurement, remote communication and remote real-time monitoring can be realized through the network, which can realize unattended without human intervention; automation and instruments have good reliability and applicable accuracy; primary investment and maintenance costs are low, which has great significance in oil production, especially in offshore oil, desert oil fields, remote oil wells and oil well testing The economic benefit of the project is excellent.

For the complex conditions in Venezuela MPE3 oilfield including high viscosity oil, high gas content oil and foamy crude oil, ShengjiPetro had designed a brand-new solution for multiphase flow meter. This solution uses dual splitter, weight measurement method and built-in high efficiency cyclone separating device to engage the meter has the characteristic of wide adaption of measurement range, high accuracy, wide range, operation stability.

For complex conditions such as high viscosity oil, high gas content oil, and foamy crude oil in Venezuela's MPE3 oilfield, ShengjiPetro has designed a new multiphase flowmeter solution. The scheme adopts double separator, weight measurement method and built-in high-efficiency cyclone separator to mesh with the flowmeter, and has the characteristics of wide measurement range, high precision, wide range and stable operation.

This device has already got the certification of Venezuela Ministry and received the high reputation of clients.

Shengji Petroleum Pumping Unit Manufacturing Plant is one of the main branches of Shengji Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales and service of pumping units. The factory has 235 employees, more than 130 sets of various large and medium-sized mechanical processing equipment, fixed assets of 12 million yuan, annual output of 1,200 pumping units, and annual sales income of 200 million yuan.

There are 4 senior engineers, 12 intermediate engineers, 7 assistant engineers, 4 senior technicians and 12 technicians in the pumping unit. Intermediate and senior workers account for more than 90% of all workers. The superb technical level of employees provides a technical guarantee for the production of high-quality pumping units.