Raw materials of API 11ax rod pump parts shall be inspected after heat treatment, and the mechanical properties, chemical composition and metallographic structure must be inspected in batches. During processing, API 11ax rod pump parts shall be inspected many times. Key points such as plunger outer diameter and pump barrel inner diameter must be comprehensively inspected.

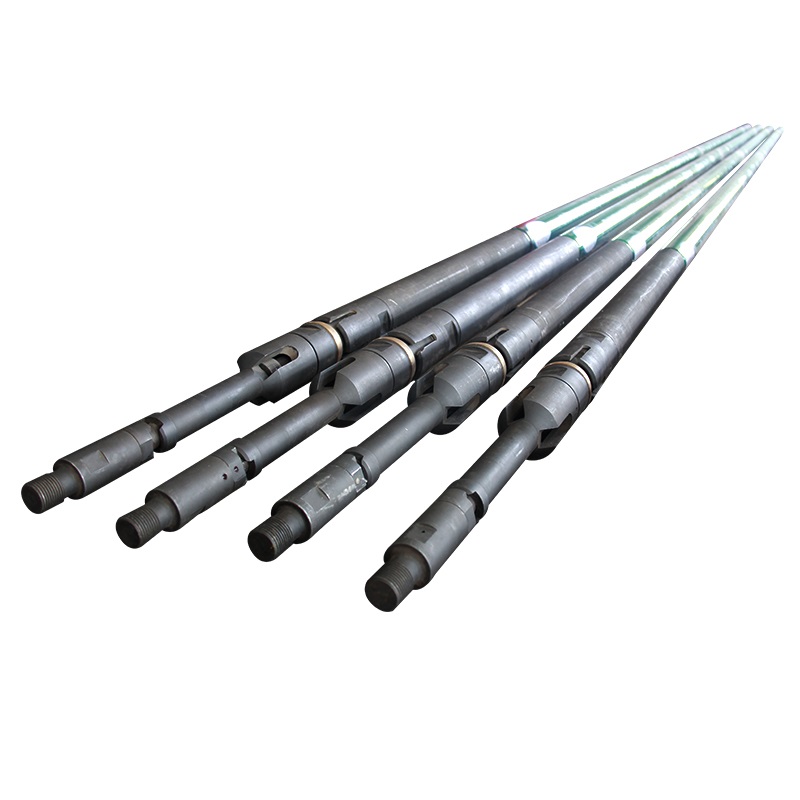

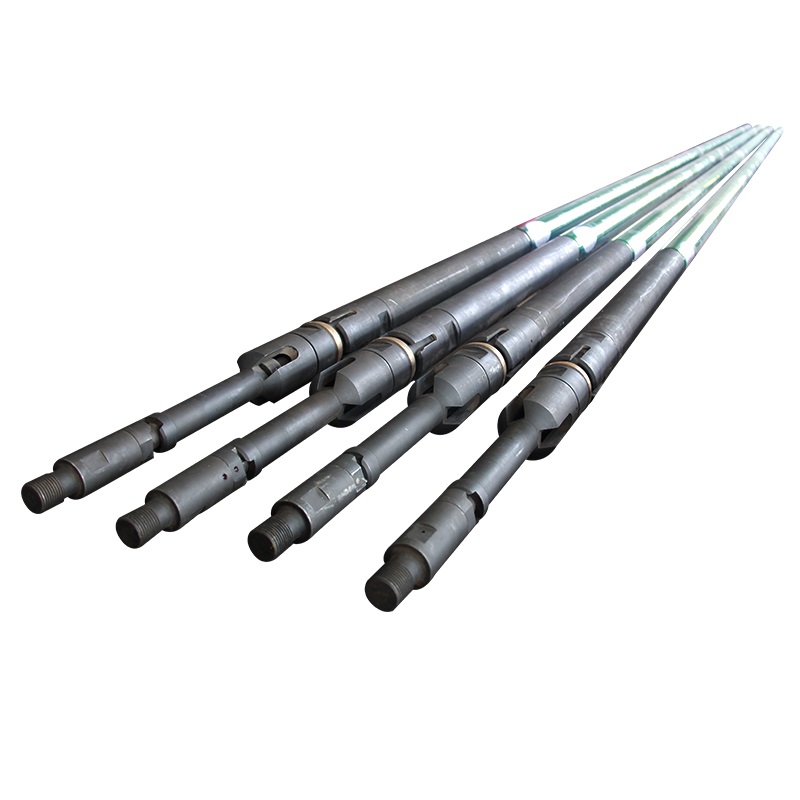

The first letter R standing for Rod (commonly called insert). Usually Insert pumps are the first choice because they can be serviced simply by pulling the sucker rod string. Insertable pumps can be removed from the well without having to remove the production tubing.

The raw material of API 11AX rod pump parts should be inspected after heat treatment, the mechanical properties, chemical compositions and metallographic structures must be inspected by batch. The API 11AX rod pump parts should be inspected several times during the processing procedure. Some key points like the outer diameter of the plunger and the inner diameter of the pump barrel should be 100% inspected.

Compared with the tubing pump, the rod type oil well pump has the characteristics of lifting the pump without the need for up and down tubing and various forms. The pump is easy to check, saves more than half of the operation time, and greatly saves the operation cost. Very suitable for deep wells.

Rod pump can be further optimized by selecting the metallurgy and coating of various components to maximize pump life in specific well conditions.

Rod pumping wells are widely used at home and abroad

If you are looking for API pump manufacturers, ShengjiPetro is your best choice.

Shengji Petroleum Pumping Unit Manufacturing Plant is one of the main branches of Shengji Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales and service of pumping units. The factory has 235 employees, more than 130 sets of various large and medium-sized mechanical processing equipment, fixed assets of 12 million yuan, annual output of 1,200 pumping units, and annual sales income of 200 million yuan.

There are 4 senior engineers, 12 intermediate engineers, 7 assistant engineers, 4 senior technicians and 12 technicians in the pumping unit. Intermediate and senior workers account for more than 90% of all workers. The superb technical level of employees provides a technical guarantee for the production of high-quality pumping units.