ShengjiPetro’s wellhead & X-mas tree factory is one of the main branches of ShengjiPetro Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales, and service of wellhead & X-mas tree. The factory has 185 employees, more than 200 sets of various large and medium-sized mechanical processing equipment, the annual output of 3500 equipment.

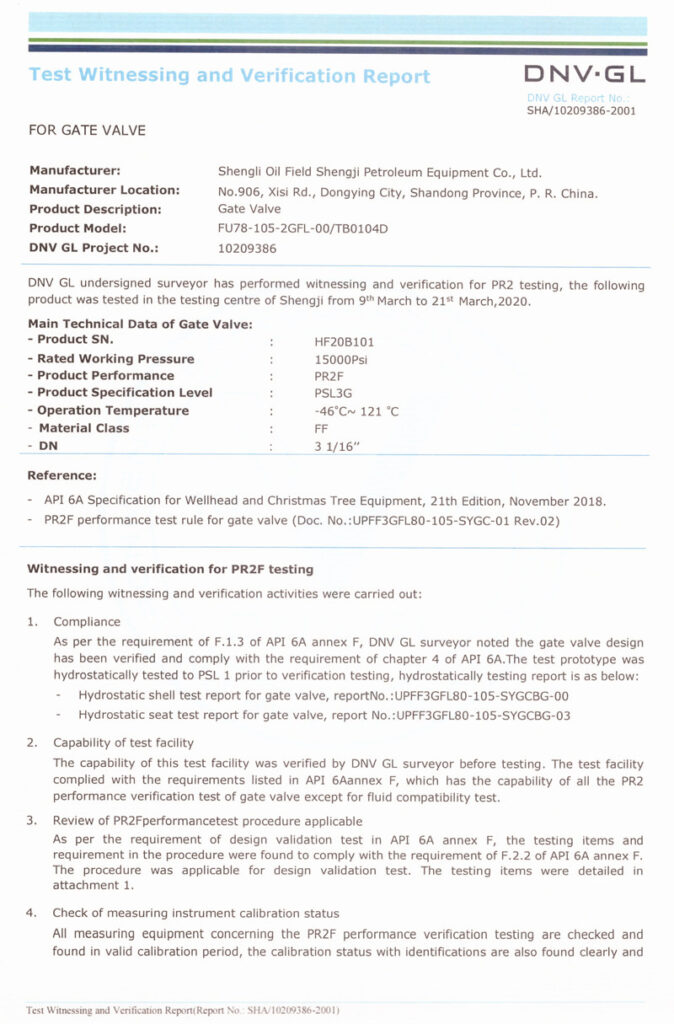

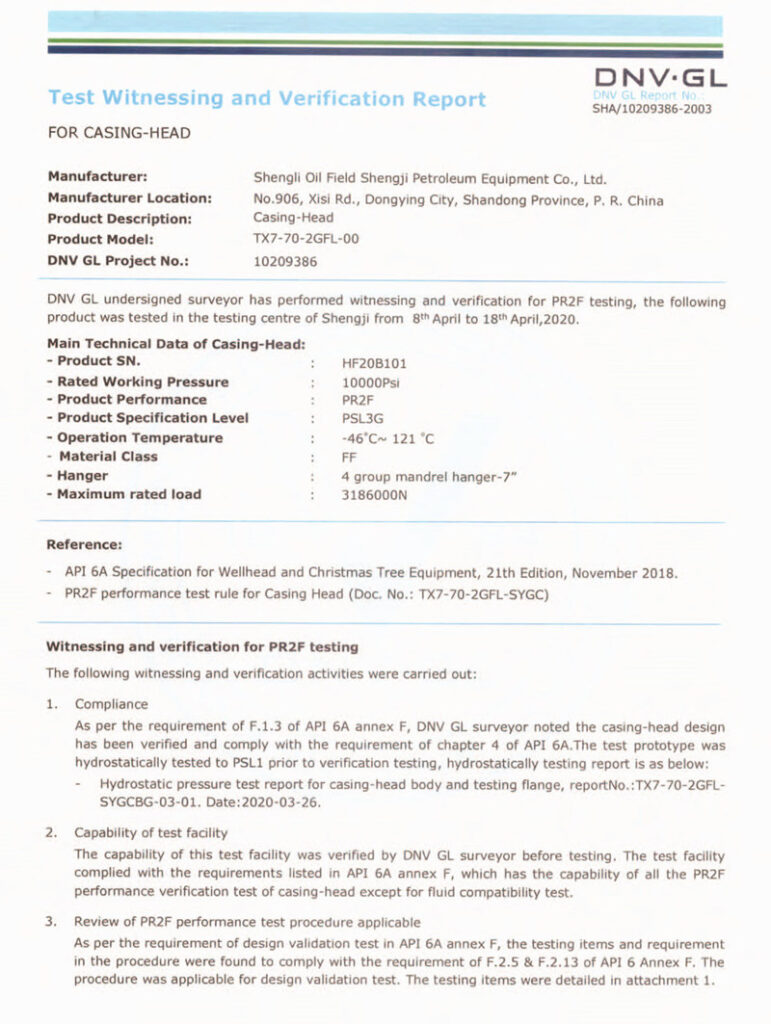

The wellhead and X-mas tree valves produced by ShengjiPetro all conform to the API 6A PR2 standard. PR2 wellhead is designed to suit severe oilfield conditions. It is mainly used in oil/gas wells with high performance requirements. The performance of all the wellhead equipment are verified by DNV verified including the casing head housing, casing head spool, tubing head spool and cross, gate valve and choke valve.

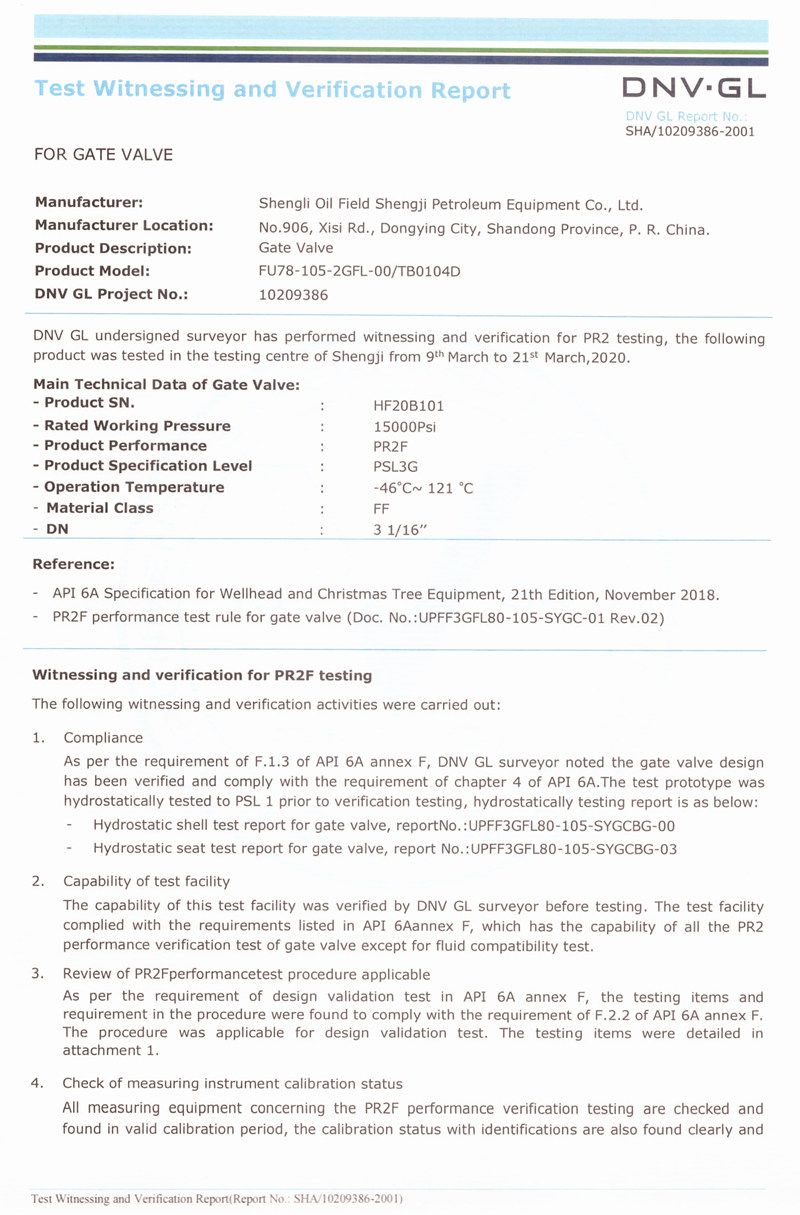

1)PR2 Gate Valve

PR2 gate valve is mainly used in the PR2 class wellhead and X-mas tree. It controls the opening and closing of fluid in the production process and is one of the core components of the wellhead and X-mas tree. However, PR2 class wellhead and X-mas tree with high pressure are always the disadvantage of Chinese oil wellhead equipment manufacturers due to their high design, manufacturing and test requirements. After two years of development and testing, ShengjiPetro gate valves have finally passed PR2 validation.

PR2 Gate Valve Experimental Parameters:

| Rated working Pressure(psi) | 15000 |

| Wellhead Nominal Diameter(in) | 3 1/16” |

| Working Temperature(℃) | -46℃-121℃ |

| Production SpecificationLevel | PSL3G |

| Performance Performance | PR2F |

| Material Class | FF |

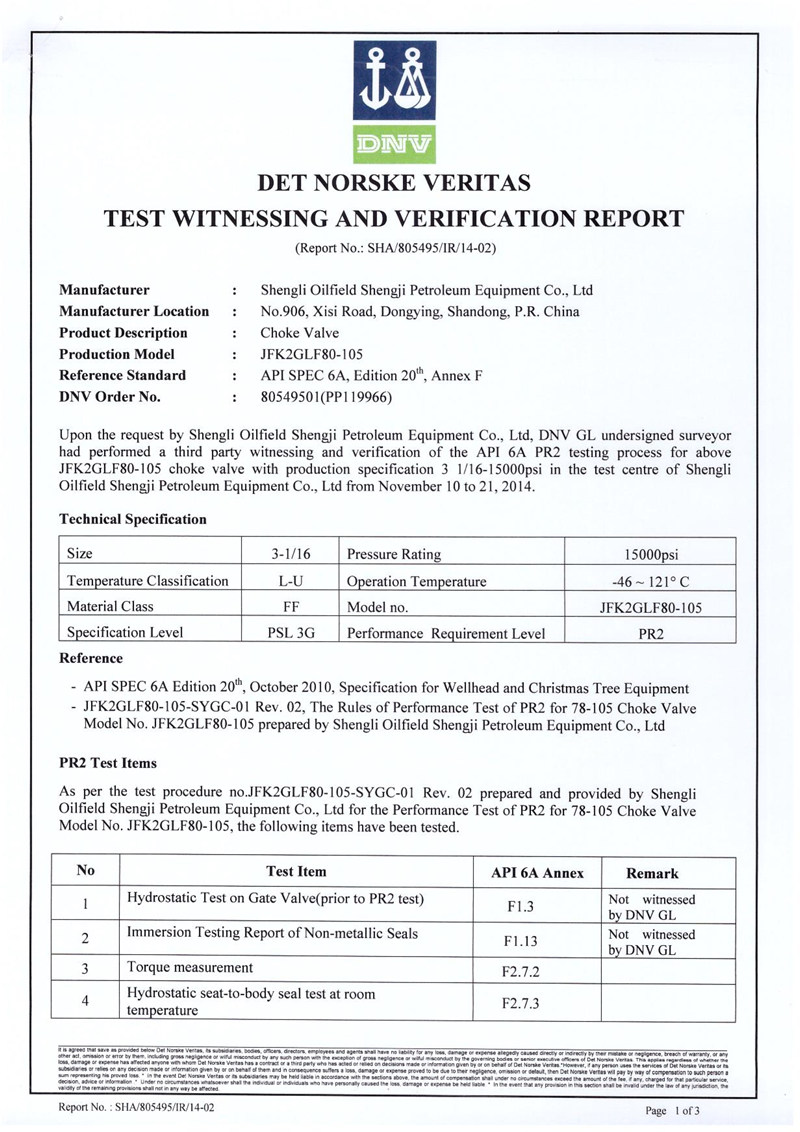

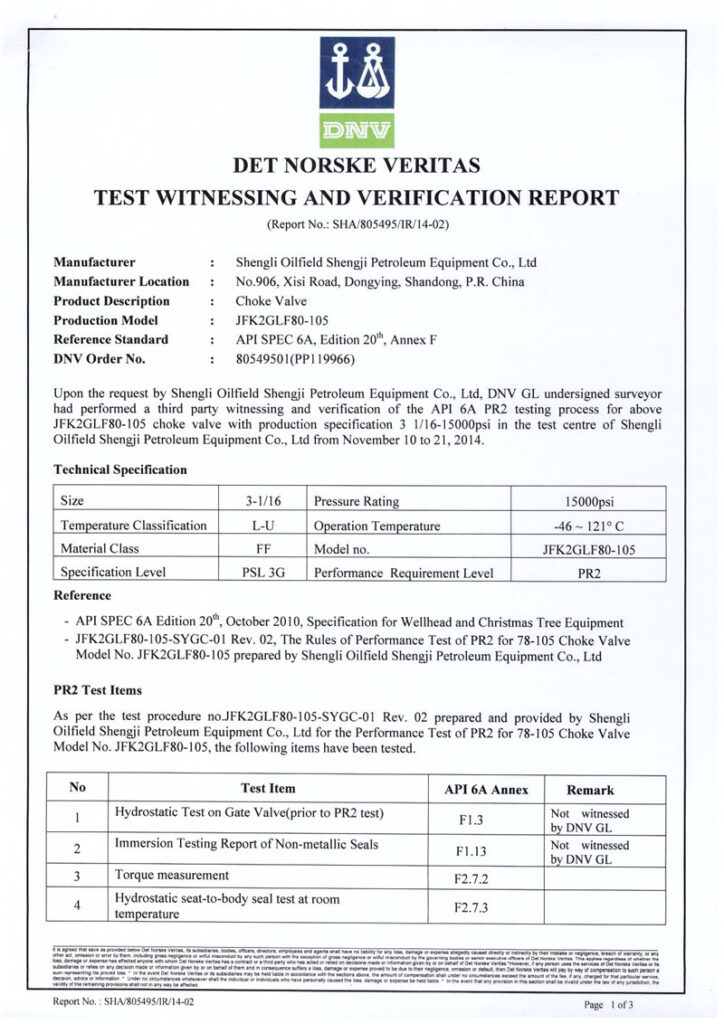

2) PR2 Choke Valve

PR2 Choke Valve Experimental Parameters:

| Rated Working Pressure(psi) | 15000 |

| Wellhead Nominal Diameter(in) | 3 1/16” |

| Working Temperature(℃) | -46℃-121℃ |

| Production Specification Level | PSL3G |

| Performance Performance | PR2 |

| Material Class | FF |

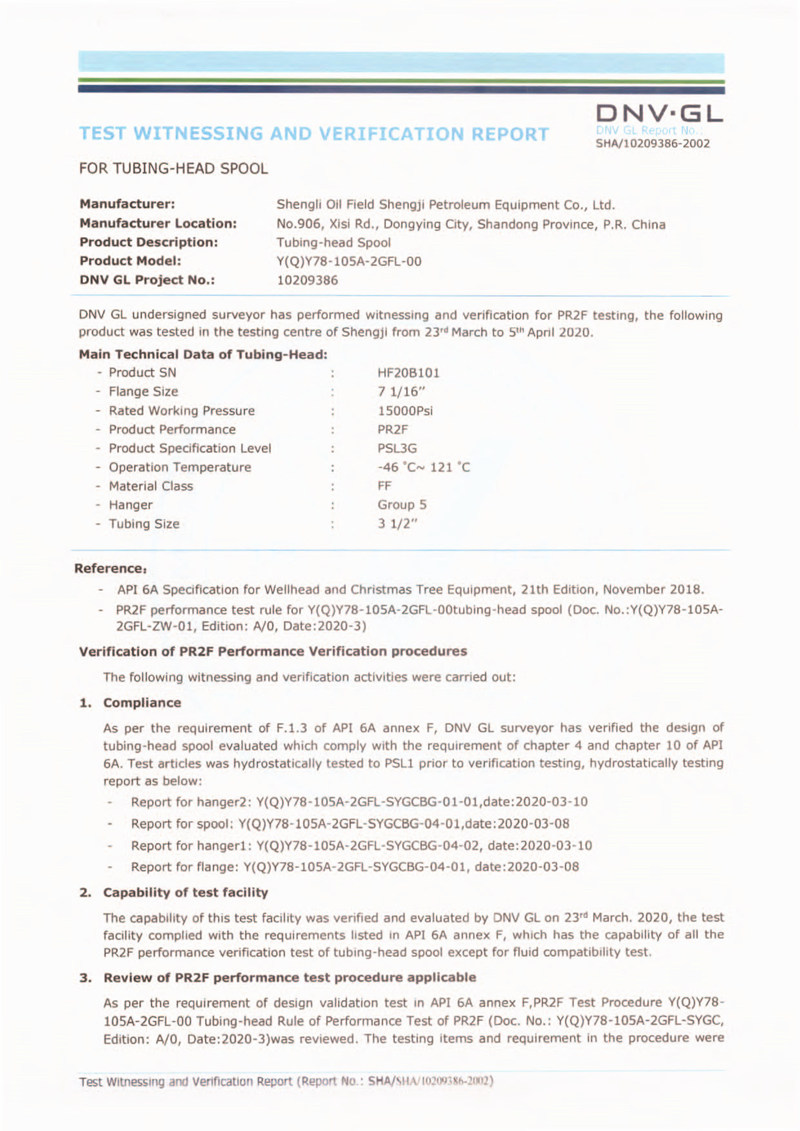

3)PR2 Tubing Head Spool

PR2 Tubing Head Spool Experimental Parameters:

| Rated Working Pressure(psi) | 15000 |

| Tubing Size (in) | 3 1/16” |

| Flange Size | 7 1/16 |

| Working Temperature(℃) | -46℃-121℃ |

| Production Specification Level | PSL3G |

| Performance Performance | PR2F |

| Material Class | FF |

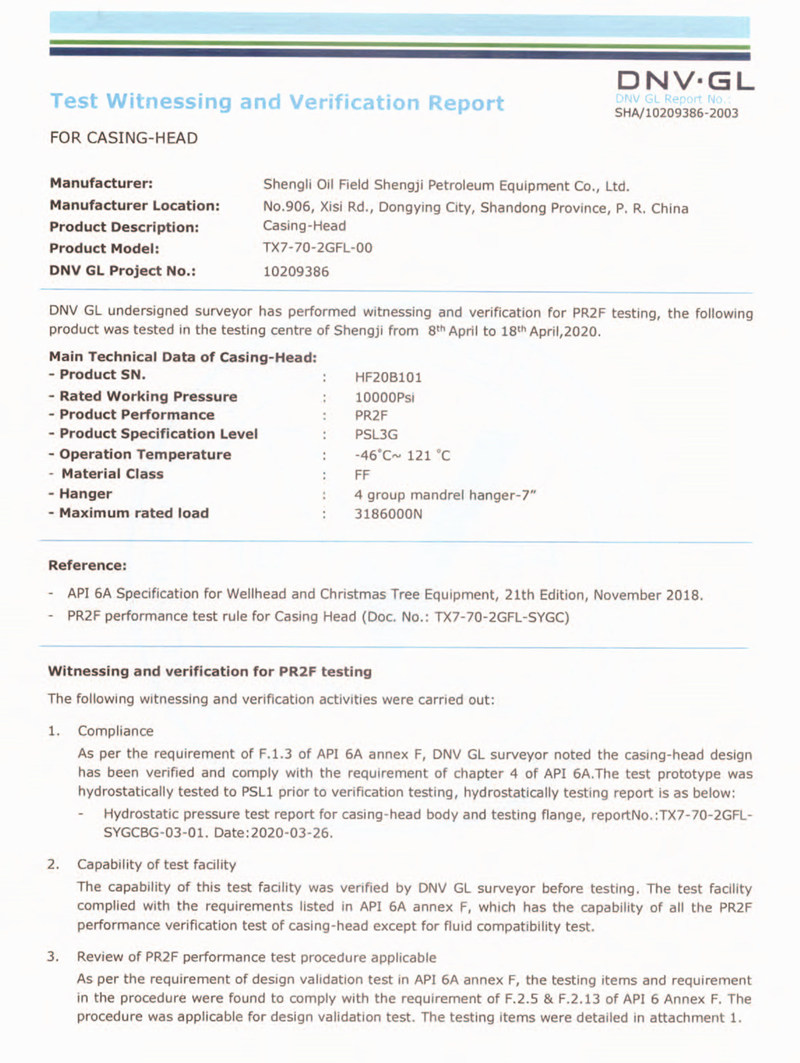

4)PR2 Casing Head

PR2 Tubing Head Spool Experimental Parameters:

| Rated Working Pressure(psi) | 15000 |

| Tubing Size (in) | 3 1/16” |

| Flange Size | 7 1/16 |

| Working Temperature(℃) | -46℃-121℃ |

| Production Specification Level | PSL3G |

| Performance Performance | PR2F |

| Material Class | FF |

Shengji Petroleum Pumping Unit Manufacturing Plant is one of the main branches of Shengji Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales and service of pumping units. The factory has 235 employees, more than 130 sets of various large and medium-sized mechanical processing equipment, fixed assets of 12 million yuan, annual output of 1,200 pumping units, and annual sales income of 200 million yuan.

There are 4 senior engineers, 12 intermediate engineers, 7 assistant engineers, 4 senior technicians and 12 technicians in the pumping unit. Intermediate and senior workers account for more than 90% of all workers. The superb technical level of employees provides a technical guarantee for the production of high-quality pumping units.