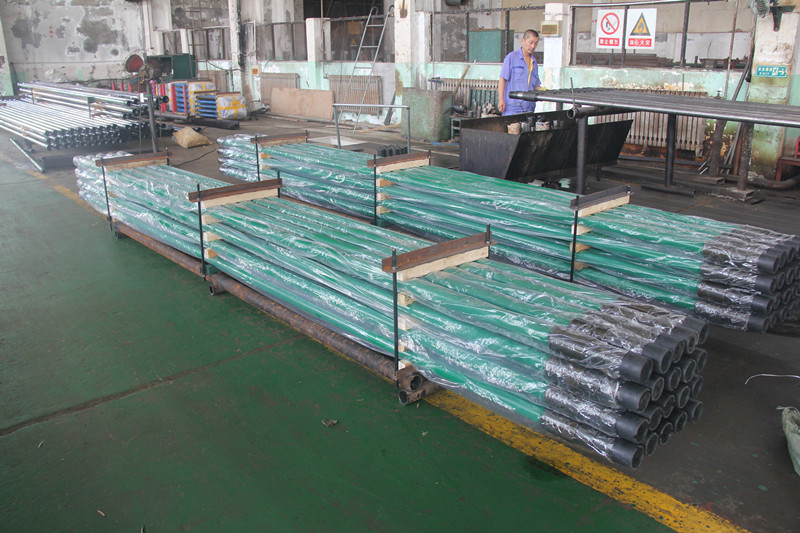

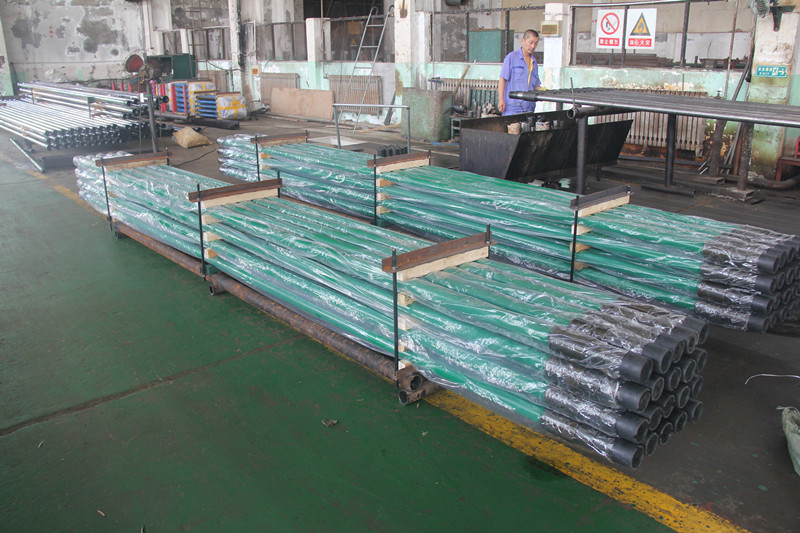

ShengjiPetro is the best quality tubing pump supplier in China. To improve the anti-corrosion property and hardness, Surface treatment is required on all the parts of API 11AX THC tubing pump according to the requirement of client and API 11AX, spray welding on plunger, chrome-plating on barrel and phosphating on all accessories. ShengjiPetro can finish spray welding process on various kinds of plungers of which the length is within 8 meters, and can complete chrome-plating on barrel with ID ranging from 1 1/16’’(26.99mm) to 5 3/4’’ (146.05 mm) and length within 34 ft (10363 mm).

API type TH pumps are heavy wall, stationary barrel, bottom anchor design tubing pumps. Available with 3 cup type hold down (THC). TH pumps give the largest possible bore size for a given tubing size, meaning the maximum amount of displacement with each stroke and therefore the greatest possible production.

THC API tubing pump is a thick wall fixed barrel pump of standard design approved by API. They are usually used to produce wells that contain more fluid than insert sucker rod pumps can. Unlike insert pumps, the working cylinder of these pumps is part of the tubing string, which enables them to discharge more fluid than insert pumps. The press is a separate part that is usually inserted into the assembly prior to delivery at site. The travelling assembly is installed at the end of the sucker rod.

The API-Type TH tubing pumps feature heavy-walls and full-barrels.

These pumps can be assembled with:

All-metal, heavy-wall barrel tubing pump combines heavy-duty construction and stroke design to achieve maximum output for any given tubing size. The integral plunger eliminates the joints that are prone to failure under the working load, and carries out precision honing from end to end to ensure that the plunger has perfect holes and improve the pumping efficiency.

APPLICATION:

These pumps are recommended for the following applications:

FEATURES:

The thick wall integral pump barrel with special coupling has good sealing performance, superior assembly strength and stiffness, and is suitable for the worst environment.

Shengji Petroleum Pumping Unit Manufacturing Plant is one of the main branches of Shengji Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales and service of pumping units. The factory has 235 employees, more than 130 sets of various large and medium-sized mechanical processing equipment, fixed assets of 12 million yuan, annual output of 1,200 pumping units, and annual sales income of 200 million yuan.

There are 4 senior engineers, 12 intermediate engineers, 7 assistant engineers, 4 senior technicians and 12 technicians in the pumping unit. Intermediate and senior workers account for more than 90% of all workers. The superb technical level of employees provides a technical guarantee for the production of high-quality pumping units.