ShengjiPetro Polished Rod Rotator can make the polished rod rotation at a constant speed, so that the sucker rod and tubing wear will be distributed in the range of 360 degrees, reduce eccentric wear, so as to prolong the service life of the sucker rod and tubing and reduce the production cost.

Be used in sucker rod pump oil production system.

Working principle: make the sucker rod rotation at s stable speed.

Effect:reduce eccentric wear and prolong the service life of the sucker rod and tubing.

Annual output of 5000 pieces.

At present, the most widely used mechanical oil recovery method is rod pump oil production. In a rod pump system, the movement of the sucker rod in the tubing is very complicated. This movement causes severe friction between sucker rod and tubing, resulting in sucker rod fracture and tubing perforation. If there is rod eccentricity in deviated wells or horizontal wells, the consequences will be more serious. Sucker rod fracture and tubing perforation will affect normal oil production and increase production costs.

In the sucker rod pump oil production system, the reciprocating motion of the sucker rod in the tubing causes the intense friction between the sucker rod and the tubing, which leads to the fracture of the sucker rod and the perforation of the oil pipe. More serious in partial deviated wells and horizontal wells.

If the sucker rod rotates at a constant speed in the sucker rod pump system, the wear will be evenly distributed in the range of 360 º to reduce eccentric wear and prolong the service life of the sucker rod. Continuous positive rotation of the sucker rod can prevent the occurrence of sucker rod tripping accident.

https://youtu.be/RsWAEEJdBHo

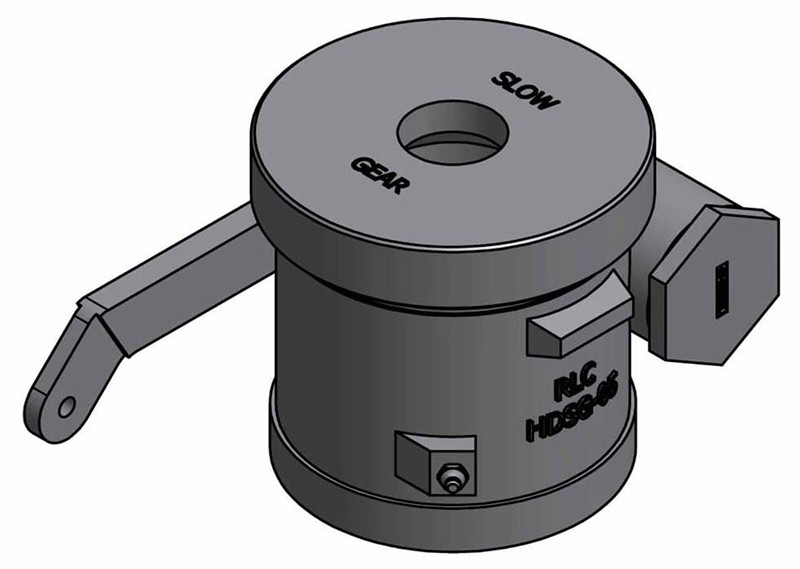

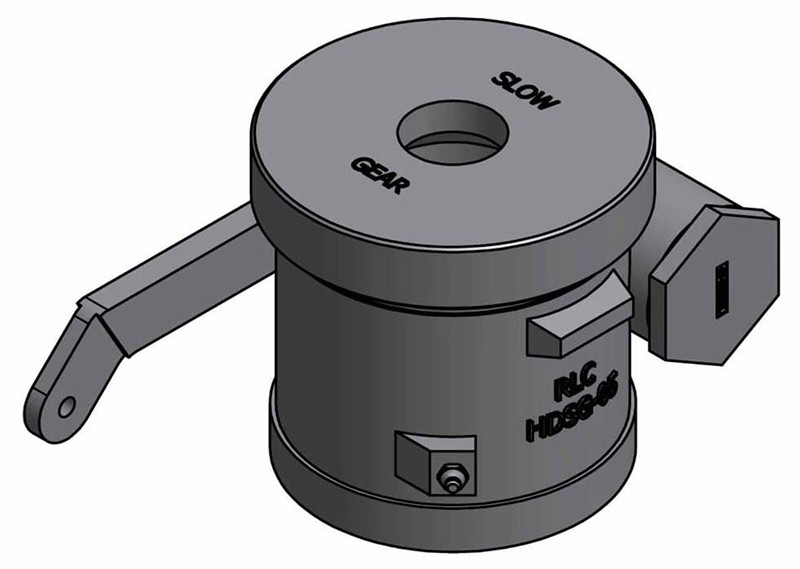

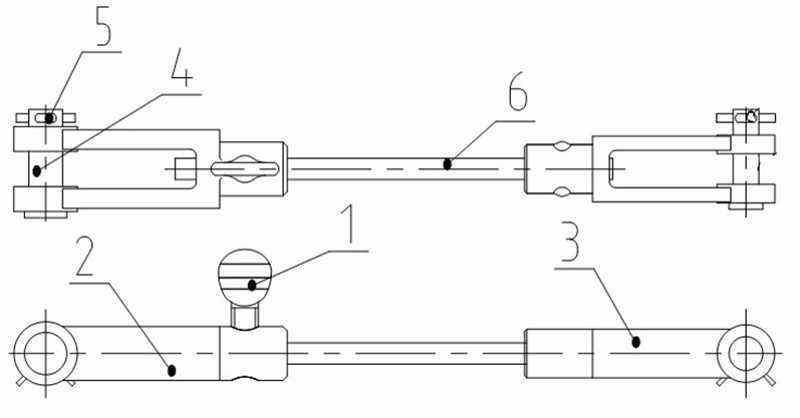

1.Rotator:(Figure 1)

Mainly consists of the following parts:1)housing 2)Cap 3)Gear 4)Worm 5)Thrust bearing 6)Sealing ring 7)Ratchet Wheel 8)Pawl 9)Deep groove ball bearing 10)Drive Rod 11)Choke Bean 12)Bushing

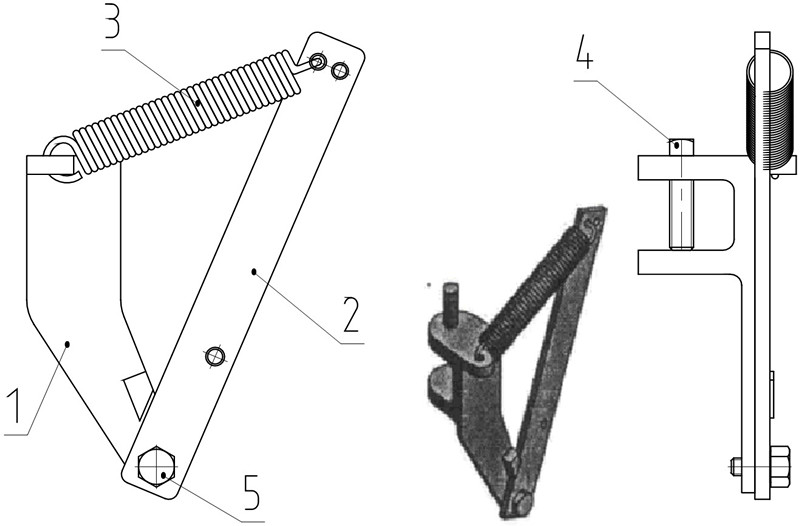

2.Connection:(Figure 2)

Mainly consists of the following parts: 1)Fixtures 2)Connecting plate 3)Tension spring 4)Fixing bolt 5)Hexagon bolt

Mainly consists of the following parts: 1)Thumbscrew 2)Movable fork 3)Fixed fork 4)Pin shaft5)Split pin 6)Wire cable

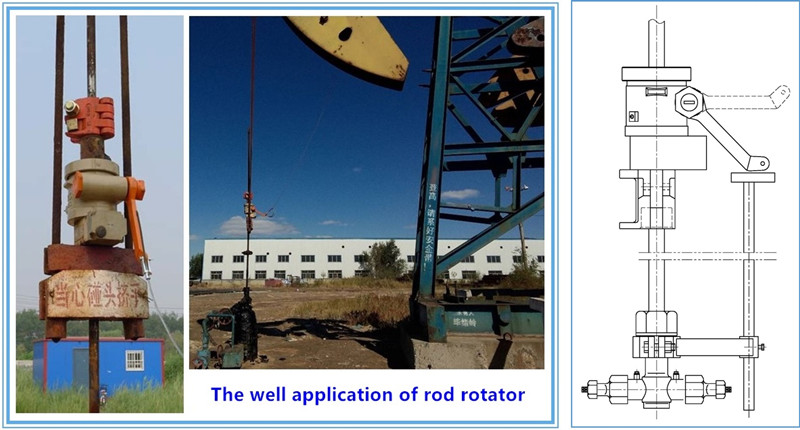

The Polished Rod Rotator is installed on the top of the rope hanger, and the sucker rod passes through the center hole. The polished rod clamp holds the polished rod and sits on the top of the polished rod rotator. When the down stroke reaches a certain position, the steel wire rope between the horsehead of the pumping unit and the polished rod rotator pulls the drive rod (or install the support rod assembly and push the drive rod by the support rod) to make it rotate at a certain angle. At this time, drive the pawl to drive the worm, and the worm gear and cap rotate a certain angle clockwise. Since the polished rod slip acts on the cap of the housing by the gravity of the sucker rod and the liquid column, the polished rod and the sucker rod also rotate to a certain angle with the rotation of the cap depending on the static friction between the rod and the cap. On the upstroke, the drive rod is repositioned by its own gravity and ready to enter a rotation cycle.

| No. | Model | Rated load (KN) | Thrust bearing model | Max. polished rod diameter(mm) | Diameter of rotating body (mm) | Minimum suspension distance(mm) | transmission ratio | Rotation angle per frequency | drift diameter (mm) | outside dimension (mm) |

| 1 | GGX16-38 | 160 | T302 | Φ38 | Φ168 | 180 | 1:40 | 2.25° | Φ46 | 282.5×215×160 |

| 2 | GGX6-28 | 60 | T182 | Φ28 | Φ113 | 120 | 1:25 | 3.6° | Φ32 | 282.5×215×142 |

| 3 | GGX6-32 | 60 | T163 | Φ32 | Φ79 | 110 | 5:31 | 14.5° | Φ32 | 301.2×161.5×111.3 |

1). Close the pumping unit and stop the sucker rod at the lowest point of the stroke of the pumping unit.

2). Pass the polished rod through the rotator, place the rotator on the top of the rope hanger, make the drive rod opposite to the horsehead of the pumping unit, and fix the polished rod clamp.

3). Mode A:Fix the connector on the horsehead of the pumping unit so that the connecting plate is opposite to the drive rod, the fixed fork of the cable is connected to the connector, and the movable fork of the other end is connected to the drive rod, and install the split pin and fix it. Adjust the steel wire cable according to the required rotation angle of the ratchet for each stroke, and fix the thumbscrew.

Mode B:Install the support on the wellhead or polished rod sealer, vertically pass the support rod through the inner hole of the support, adjust the height of the support rod according to the rotation angle of the ratchet for each stroke, and tighten the screw.

4). Start the pumping unit and test it to ensure that the rotator can work normally.

Shengji Petroleum Pumping Unit Manufacturing Plant is one of the main branches of Shengji Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales and service of pumping units. The factory has 235 employees, more than 130 sets of various large and medium-sized mechanical processing equipment, fixed assets of 12 million yuan, annual output of 1,200 pumping units, and annual sales income of 200 million yuan.

There are 4 senior engineers, 12 intermediate engineers, 7 assistant engineers, 4 senior technicians and 12 technicians in the pumping unit. Intermediate and senior workers account for more than 90% of all workers. The superb technical level of employees provides a technical guarantee for the production of high-quality pumping units.