ShengjiPetro has more than 40 years of experience in oil wellhead and API 6A valve production, with advanced manufacturing and testing equipment, can produce a variety of pressure levels, material levels, specification levels of well control equipment. After more than 20 years of development, thermal wellhead has formed a variety of products, used in many oilfields in the world. ShengjiPetro’s thermal production wellheads are mainly of the following types:

Conventional steam injection and oil recovery wellhead is low pressure and high temperature oil wellhead, which is connected by a clamp or flange:

Clamped thermal recovery wellhead:

Feature

1)Clamp type connection, easy to operate

2)Wedge gate valve, small size and light weight

3)The stem seal of valve is a high temperature resistant composite seal. The seal between valve plate and valve seat and the seal between valve body and valve seat are both metal seals. High temperature seal is reliable.

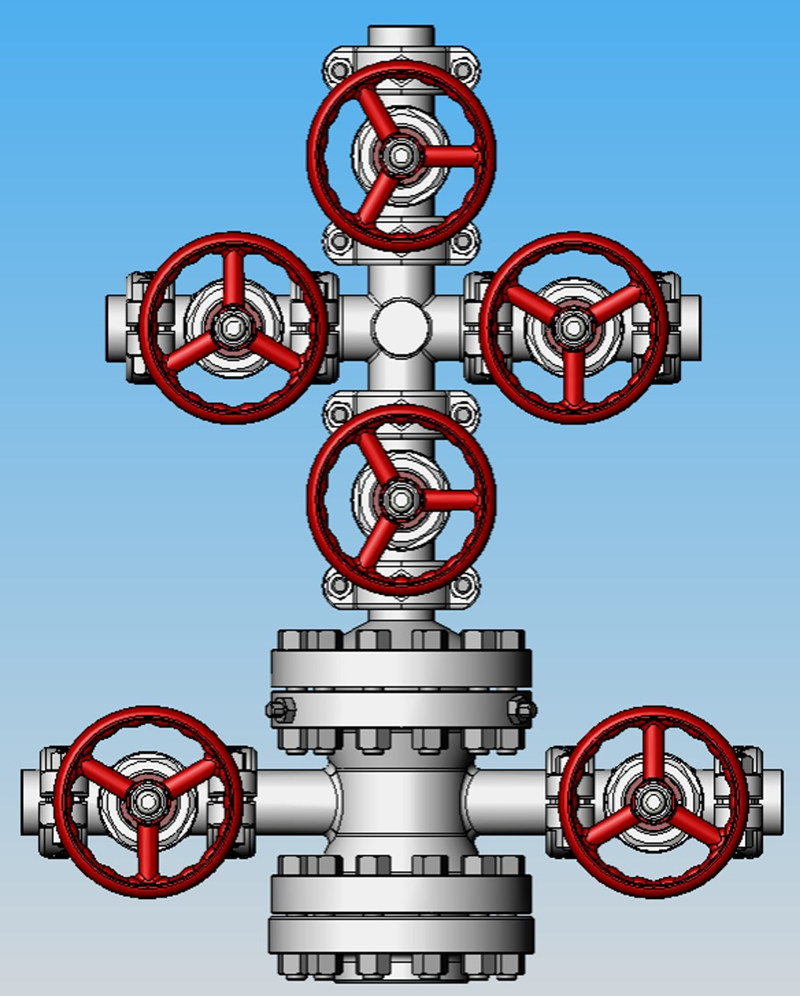

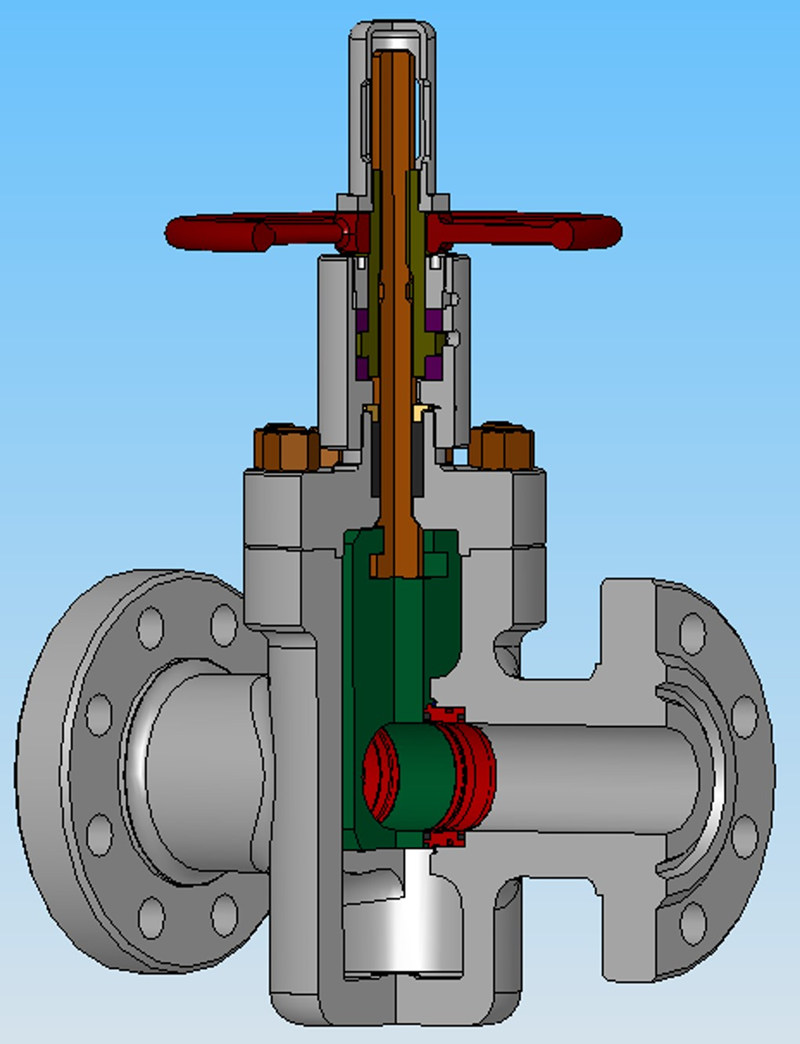

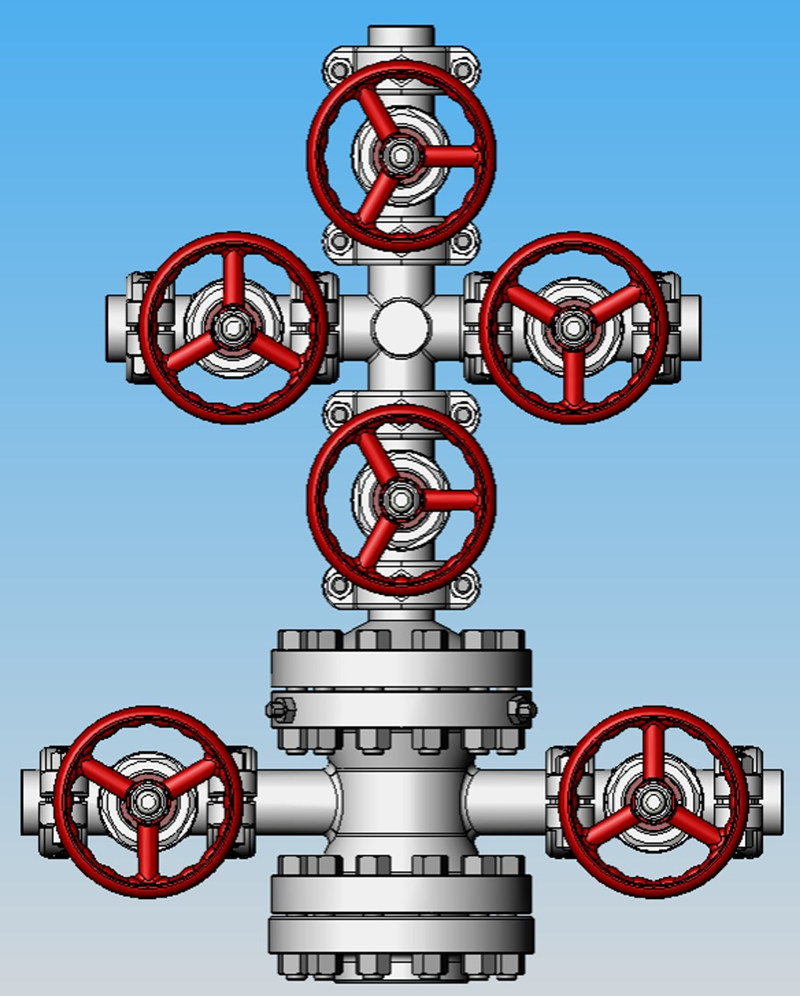

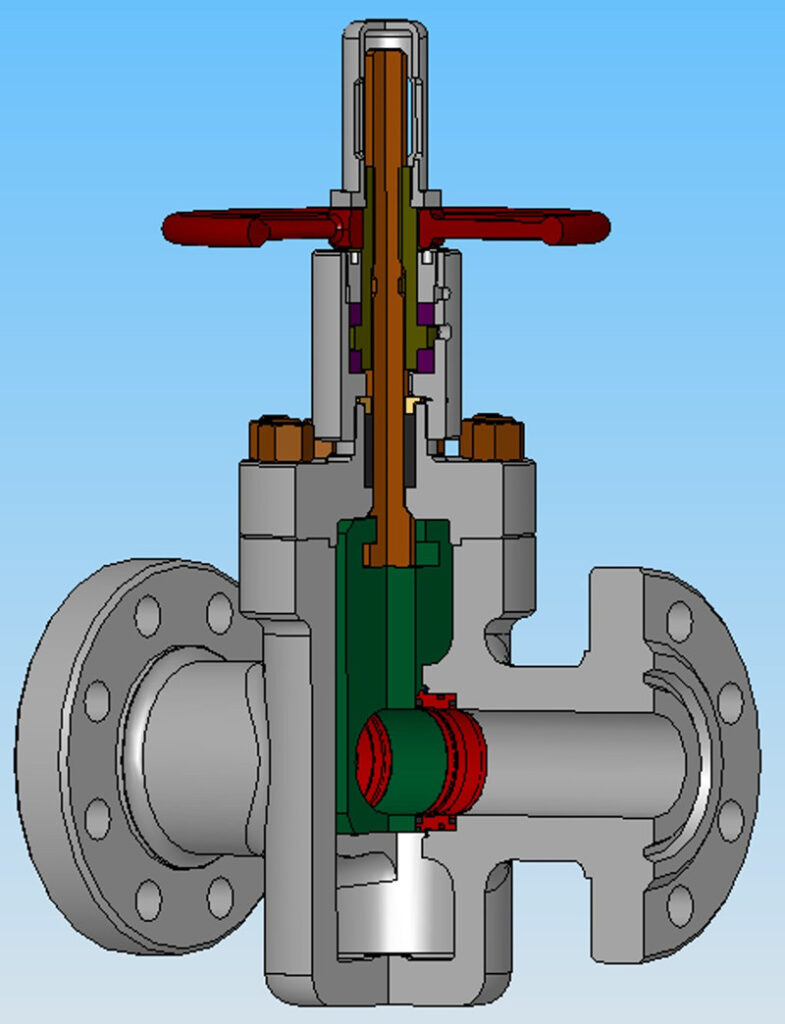

Flanged thermal recovery wellhead:

Feature

1).Flange connection. The high temperature and high pressure seal in the connection is reliable.

2).The valve is a rising rod structure. The hand wheel is equipped with a guard which can intuitively check the opening or closing conditions of the valve. and it has the function of preventing sand and dust.

3)The surface of valve seat and valve plate is sprayed with hard alloy. The seal between valve seat and valve body is high temperature resistant and non-metal seal with good performance.

The stem seal is a high temperature resistant composite seal. There is no leakage under high temperature and high pressure. After thermodynamic calculation, the parts with pressure and load are all reliable and safe under high temperature.

Shengji Petroleum Pumping Unit Manufacturing Plant is one of the main branches of Shengji Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales and service of pumping units. The factory has 235 employees, more than 130 sets of various large and medium-sized mechanical processing equipment, fixed assets of 12 million yuan, annual output of 1,200 pumping units, and annual sales income of 200 million yuan.

There are 4 senior engineers, 12 intermediate engineers, 7 assistant engineers, 4 senior technicians and 12 technicians in the pumping unit. Intermediate and senior workers account for more than 90% of all workers. The superb technical level of employees provides a technical guarantee for the production of high-quality pumping units.