- 50+ Years of Petroleum Equipment Manufacturing Experience

- ISO ,CE, Standard Qualified

- 200+ national invention patents and utility model patents

- 70 countries are covered by our products and service.

- 5 wholly-owned subsidiaries in NA, SA and Europe

- Comprehensive enterprise integrating design, R & D, manufacturing and oilfield services.

- High-tech enterprise with provincial technology centers and engineering laboratories.

- One-stop solution for oil recovery.

About Sanjack Peru: Your Your Best China Petro Equipment Supplier

About Sanjack Peru: Your Best China Petro Equipment Supplier

SANJACK PERU ,established in 1964, is a comprehensive enterprise integrating design, R & D, manufacturing and oilfield services. SANJACK PERU PETROLEUM overall floorage is more than 600,000 square meters with more than 1200 advanced equipments and 1,500 employees. SANJACK PERU PETROLEUM has 18 production plants, 12 pubsidiaries and several offices around the main oilfield in the world.

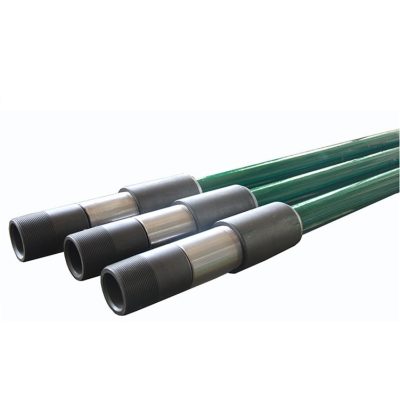

Diversified business covers seven blocks: conventional drilling & recovery equipment, complete sets of thermal recovery equipment, anti-corrosion and anti-abrasion solution, multiphase flowmeter solution, Automatic workover system, tertiary oil recovery, oil and gas mixed transportation equipment. Products are exported to North America, South America, Asia, Middle East, Africa, CIS and other regions. Sales value is $150 million. SANJACK PERU PETROLEUM has obtained 178 national patents and the international certificates, including API, ISO9001, HSE, ASME, CE, PR2 and etc.

Why Sanjack Peru Can Be Your Reliable Petroleum equipment Supplier?

50 Years Petroleum Equipment Manufacturing Experience

Customized products

24/7 Online Support

ISO ,CE,Standard Qualified

Quick respond

Flexible Payment Options

Where Our Client’s petro Equipment Equipments Are Sold

Sanjack Peru company Key Feature

- Leading products have formed fourteen major series and nearly a thousand varieties

- Pumping unit suppliers of Amrican Schlumberger withthe lowest failure rate in China.

- Brass sucker rod pump with anti-corrosion and wear-resistant properties

- PR2 certificated by DNV for valves, wellhead and X-mas tree

- First company that provide overall anti-corrosion and anti-wear equipment in China

- Fourth-generation nickel-based tungsten plating technology adopted

- One-stop thermal recovery solutions provided

- High level vaccum insulation tubing&casing

- The only foreign flowmeter enterprise certified by the Ministry of Energy and Mineral Resources in Venezuela

- Automation and intelligence equipment can be produced such as automatic workover rig