The oil wellhead equipment factory of ShengjiPetro is one of the main branches of ShengjiPetro Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales, and service of wellhead and Christmas tree equipment. The factory has 185 employees, more than 200 sets of various large and medium-sized mechanical processing equipment, the annual output of 3500 equipment.

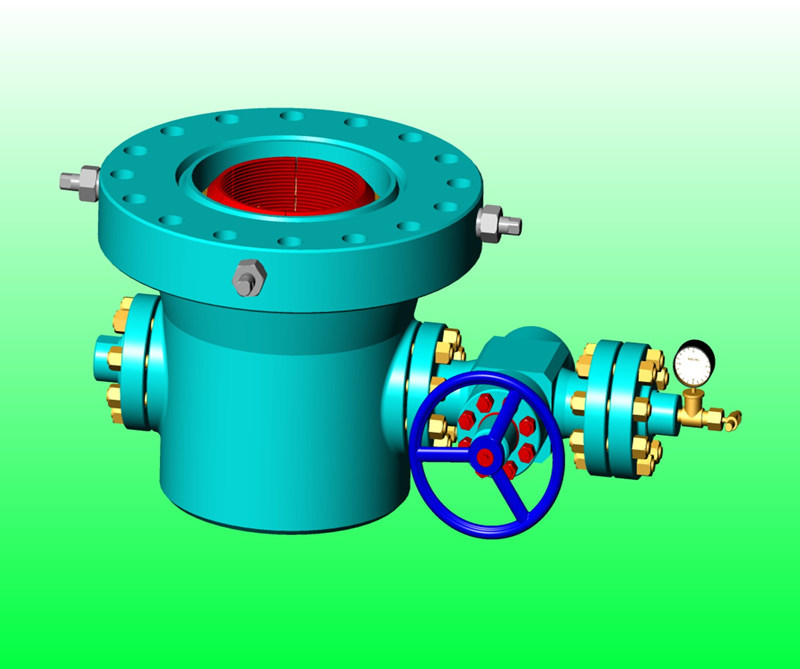

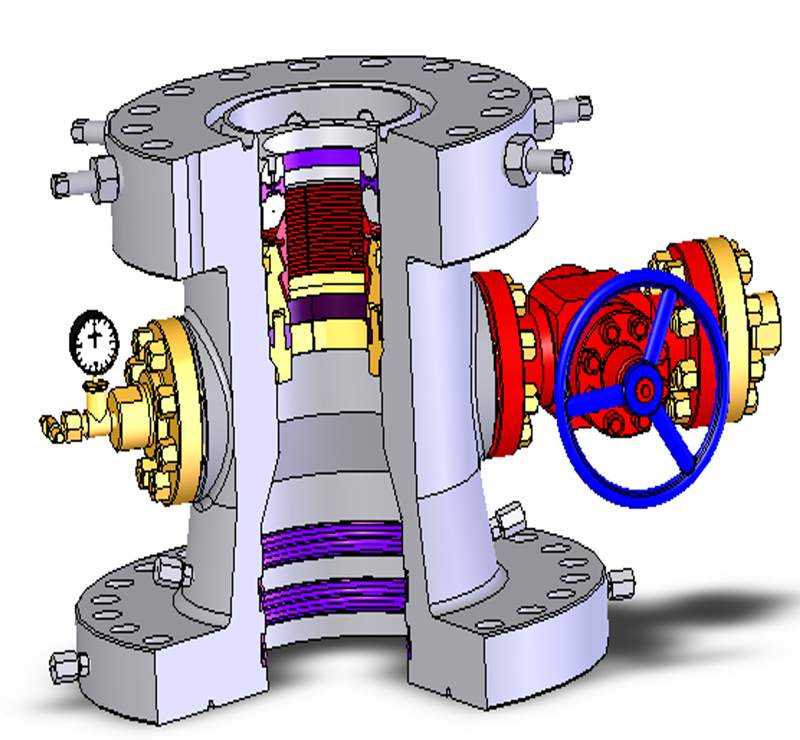

1).Casinghead

C-22 casingheads feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

Features a 45°landing shoulder capable of supporting maximum loads

Prevents test plugs from wedging under pressure

Line Pipe Outlets

Studded Side Outlets

C-21 and C-22 slip-type casing hangers

Mandrel style casing hangers

API-6A, PSL-1, DD, L-U,PR-1

Additional sizes available upon request

AvailableinC-29 profile (Available upon request)

C-22-BP casing heads are supplied with lockscrews for wear bushing retention

C-22-L and C-29-L casinghead are supplied with a full set of lockscrews for mandrel casing hanger and pack off retention (Available upon request)

Slip-on weld

Slip-on weld with O-ring

Threaded

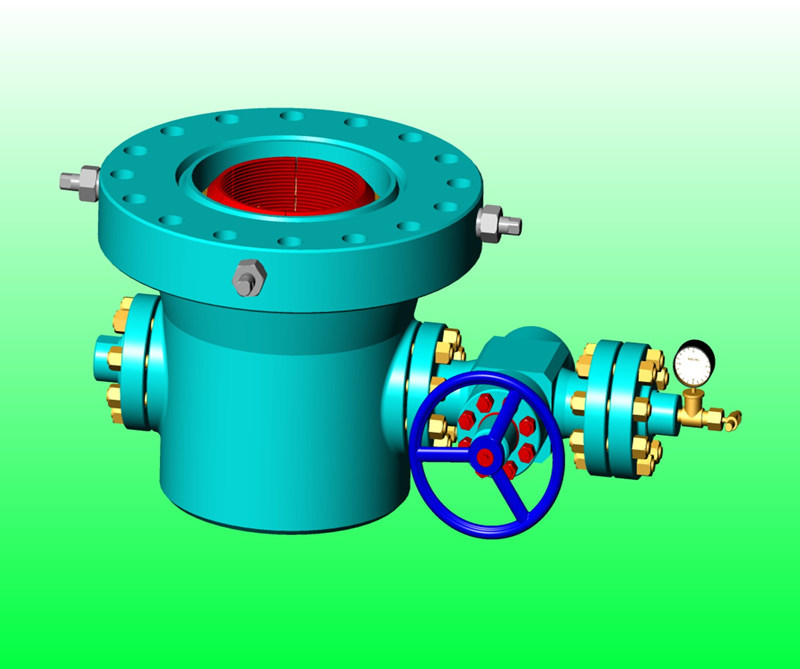

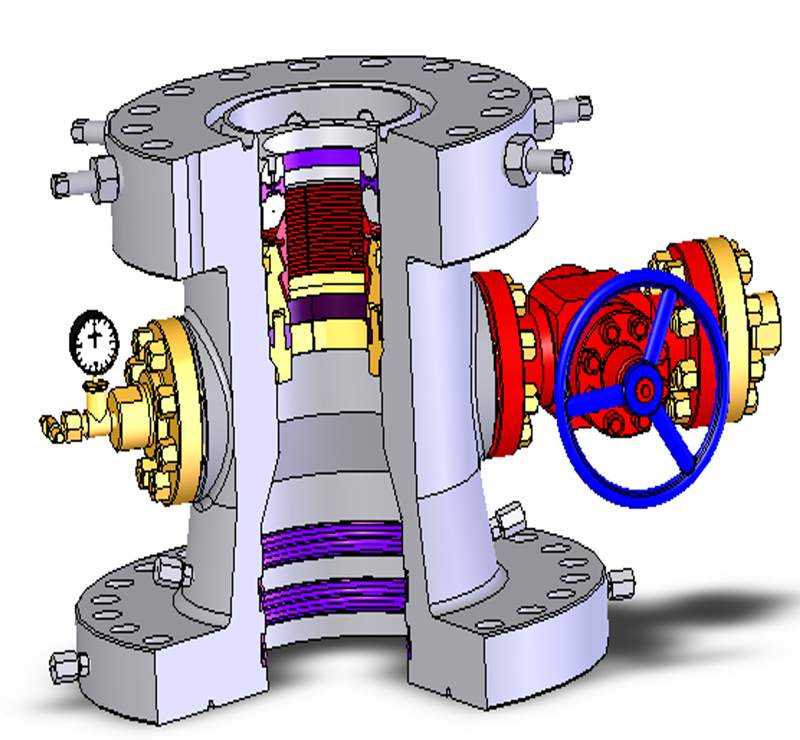

2). Casing Spools

C-22 casing spools feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

Features a 45° landing shoulder capable of supporting maximum casing loads.

Prevents test plugs from wedging under pressure.

Line Pipe Outlets.

Studded Side Outlets.

C-21 and C-22slip- type casing hangers.

Mandrel style casing hangers.

API-6A, PSL-1, DD, L-U,PR-1

Additional sizes available upon request.

Available in C-29 profile (Available upon request).

C-22-BP casing spools are supplied with (2) lock screws for wear bushing retention.

C-22-L and C-29-L casing spools are supplied with a full set of lockscrews for mandrel casing hanger and pack off retention (Available upon request)

PE/BG bottom for use with PE secondary seal bushing (Standard).

HPE bottom, for use with HPE secondary seal bushing for high pressure applications (Available upon request).

3).Tubing Spools

Tubing heads feature a versatile straight bore design for single and multiple completions. This design accepts all TC series tubing hangers and easily converts from a single completion to multiple completions with the addition and alignment pin. The tubing heads are manufactured in API 6A low alloy steel or stainless steel.

Basic Parameters

Nominal size of top flange (in):

Nominal size of bottom flange (in):

7-1/16, 11, 13-5/8.

Bottom flange working pressure (PSI):

2M, 3M, 5M, 10M, 15M, 20M.

Nominal size of side exit (in):

2-1/16, 2-9/16.

Features: a 45° landing shoulder capable of supporting maximum loads.

Line Pipe Outlets

Studded Side Outlets

API-6A, PSL-1, DD, L-U, PR-1 (3M-5M)

API-6A, PSL-2, DD, L-U, PR-1 (10M)

WTCM tubing heads accept a wide variety of tubing hanger styles including mandrel and wrap-around.

PE/BG bottom, for use with PE secondary seal bushing (Standard).

HPE bottom, for use with HPE secondary seal bushing for high pressure applications (Available upon request).

Additional sizes available upon request.

Available with ET (Integral) style lock screws.

Flanged top Tubing Heads available with slip-on weld or threaded bottoms.

Shengji Petroleum Pumping Unit Manufacturing Plant is one of the main branches of Shengji Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales and service of pumping units. The factory has 235 employees, more than 130 sets of various large and medium-sized mechanical processing equipment, fixed assets of 12 million yuan, annual output of 1,200 pumping units, and annual sales income of 200 million yuan.

There are 4 senior engineers, 12 intermediate engineers, 7 assistant engineers, 4 senior technicians and 12 technicians in the pumping unit. Intermediate and senior workers account for more than 90% of all workers. The superb technical level of employees provides a technical guarantee for the production of high-quality pumping units.