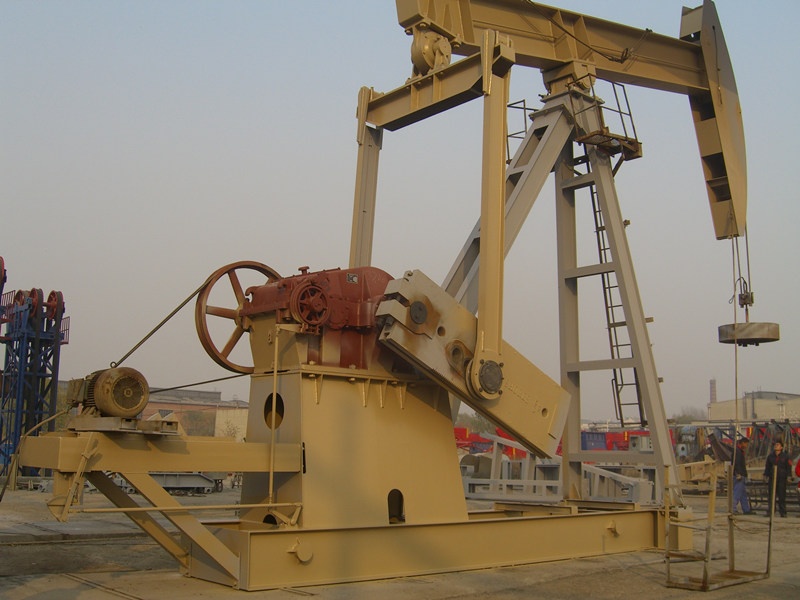

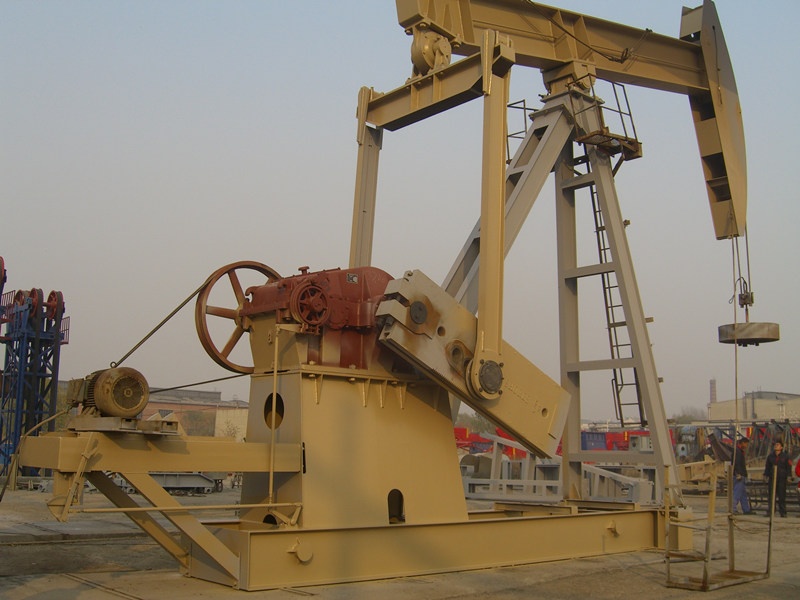

RM pumping unit is designed on the basis of conventional beam pumping unit, which can change the time of up and down stroke of the pumping unit and is suitable for heavy oil recovery.

RM (Reverse Mark) pumping unit is based on the conventional beam pumping unit, which optimizes the four-rod structure and designs the out-of-phase angles on the crank. The operation of conventional beam pumping unit is limited by its own structure, which has low stability, low efficiency and high energy consumption. RM pumping units with crank out-of-phase angles take different time to run up and down strokes. The longer upstroke time and the lower average speed of the horsehead can increase the downpump filling coefficient and extract more oil for the same unit of energy consumption. It's more efficient and uses less energy.

| Model | ||||||||

| RM912D-427-192 | RM912D-427-168 | RM912D-365-168 | RM640D-365-168 | RM640D-365-144 | RM456D-365-120 | RM456D-305-144 | ||

| Basic Parameters | Rated Polish Rod Capacity (lbs) | 42,700 | 42,700 | 36,500 | 36,500 | 36,500 | 36,500 | 30,500 |

| Stroke Length (in) | 192/168/144/ | 168/144/120 | 168/144/120 | 168/144/120 | 144/120/100 | 120/100/86 | 144/123/101 | |

| Max. Stroke Frequency (r/min) | 8 | 8 | 8 | 10 | 10 | 10 | 10 | |

| Balanced Type | Crank Balanced | |||||||

| Crank Direction | Clockwise | |||||||

| Gear Reducer | Rated Torque(in.lbs) | 912,000 | 912,000 | 912,000 | 640,000 | 640,000 | 456,000 | 456,000 |

| Model | 912D | 912D | 912D | 640D | 640D | 456D | 456D | |

| Gear Type | Double circular arc gear reducer or Involute gear reducer | |||||||

| Reducing Ratio | 28.79 | 28.79 | 28.79 | 28.363 | 28.363 | 28.255 | 28.255 | |

| Center Range (in) | 48.43 | 48.43 | 48.43 | 41.34 | 41.34 | 39.37 | 39.37 | |

| Center Height (in) | 30.91 | 30.91 | 30.91 | 25.98 | 25.98 | 25.59 | 25.59 | |

| Oil Storage quantity (U.S. Gal) | 180 | 180 | 180 | 106 | 106 | 100 | 100 | |

| Lubricant | 20# Gear lubricant in winter,200# Gear lubricant in summer | |||||||

| Sheave Diameter(in) | 50" | 50" | 50" | 50" | 50" | 44" | 44" | |

| Sheave groove type | 7C | 7C | 7C | 6C | 6C | 5C | 5C | |

| Balance Assembly | Weight of Cranks (Lbs) | 6489×2 | 6489×2 | 6404×2 | 6489×2 | 6404×2 | 5651×2 | 5651×2 |

| Wrist Pin bore Positions (in) | 45 | 45 | 45 | 45 | 45 | 38.98 | 38.98 | |

| 36.54 | 36.54 | 36.54 | 36.54 | 36.54 | 31.38 | 31.38 | ||

| 28.07 | 28.07 | 28.07 | 28.07 | 28.07 | 23.78 | 23.78 | ||

| Wire Line | Type | Φ32(6*37+IWR-1770 MPa) | Φ32(6*37+IWR-1770 MPa) | Φ32(6*37+IWR-1770 MPa) | Φ32(6*37+IWR-1770 MPa) | Φ32(6×37+IWR-1770 MPa) | Φ32(6*37+IWR-1770 MPa) | Φ32(6*37+IWR-1770 MPa) |

| Length (in) | 508 | 460 | 460 | 460 | 410 | 350 | 410 | |

| Structure Unbalance (lbs) | -2700 | -940 | -900 | -900 | 230 | 590 | -500 | |

| Overall Dimensions L*W*H (in) | 566×139×398 | 538×139×369 | 538×139×369 | 530×139×369 | 502×139×357 | 451×139×309 | 479×139×321 | |

https://youtu.be/WJtQwd4BeS0

The RM pumping unit has changed the connection mode between the beam and the beam, and the tail of the beam is at an Angle of 20°. According to calculation, this structure can make the four-bar mechanism of the pumping unit operate more stably, reduce the impact force of load on the connecting bolts, and ensure the service life under the maximum impact load.

Shengji Petroleum Pumping Unit Manufacturing Plant is one of the main branches of Shengji Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales and service of pumping units. The factory has 235 employees, more than 130 sets of various large and medium-sized mechanical processing equipment, fixed assets of 12 million yuan, annual output of 1,200 pumping units, and annual sales income of 200 million yuan.

There are 4 senior engineers, 12 intermediate engineers, 7 assistant engineers, 4 senior technicians and 12 technicians in the pumping unit. Intermediate and senior workers account for more than 90% of all workers. The superb technical level of employees provides a technical guarantee for the production of high-quality pumping units.