ShengjiPetro has strong capacity of research, design and manufacturing pumping unit, the annual production reach 1000 sets; the company has welding and machining workshop 17,942 square meters, take up 64,952 square meters; complete inspection and test equipment, and has more than 130 types of advanced production facilities.

With 30 years of experience, ShengjiPetro is devoted to designing, researching and developing pumping units. It has an annual sales volume of up to 1200 units. ShengjiPetro pumping unit cover the API conventional and unconventional pumping units. Relying on technical strength, complete equipment, scientific production fixture and strict production process; ShengjiPetro has become the pumping unit supplier for most famous companies globally. This is based on first-class quality, such as: Sentry, Shores, Schlumberger, PDO, OMV, etc. With the high quality and low failure rate, ShengjiPetro pumping unit is widely acclaimed by customers.

ShengjiPetro can provide a wide range of API pumping unit depending on users' requirements. They come with a 3-year warranty. ShengjiPetro API units are available according to customer requests. They can choose from double circular arc gear reducer or involute gear reducer. ShengjiPetro has nearly 200 pumping unit processing equipment and a complete production tooling that guarantees accuracy in the manufacturing process. By improving the supporting equipment, scientific processing technology, strict quality control, superb technical level; ShengjiPetro API Pump jacks are also suitable for inferior working conditions. These API pumping units are reliable and stable, hence their popularity among customers since ShengjiPetro uses forging for key parts and have low failure rates.

https://youtu.be/eMb0to6Cqxk

| Detailed Parameters | |||||||||||||||||||

| Model | C912D-365-168TH | C640D-365-168TH | C640D-365-144TH | C640D-305-168TH | C456D-365-120TH | C456D-305-168TH | C456D-305-144TH | C456D-256-144TH | C320D-305-120TH | C320D-256-120TH | C320D-305-100TH | C320D-256-100TH | C228D-246-86TH | C228-213-100 | C160D-200-74TH | C160D-173-86TH | C114D-173-64TH | C80-133-54TH | |

| Basic Parameters | Rated Polish Rod Capacity (lbs) | 36,500 | 36,500 | 36,500 | 30,500 | 36,500 | 30,500 | 30,500 | 25,600 | 30,500 | 25,600 | 30,500 | 25,600 | 24,600 | 21,300 | 20,000 | 17,300 | 17,300 | 13,300 |

| Stroke Length (in) | 168/144/120 | 168/144/120 | 144/120/100 | 168/144/120 | 120/100/86 | 168/145/124 | 144/123/101 | 144/124/106 | 120/100/86 | 120/103/87 | 100/86/70 | 100/86/70 | 86/74/61 | 100/86/70 | 74/63/51 | 86/74/61 | 64/54/44 | 54/45/36 | |

| Max. Stroke Frequency (r/min) | 8 | 10 | 10 | 14 | 10 | 8 | 8 | 14 | 10 | 10 | 12 | 10 | 10 | 10 | 10 | 10 | 12 | 12 | |

| Balanced Type | Crank Balanced | ||||||||||||||||||

| Crank Direction | Clockwise/Counterclockwise | ||||||||||||||||||

| Gear Reducer | Rated Torque(in.lbs) | 912,000 | 640,000 | 640,000 | 640,000 | 456,000 | 456,000 | 456,000 | 456,000 | 320,000 | 320,000 | 320,000 | 320,000 | 228,000 | 228,000 | 160,000 | 160,000 | 11,400 | 80,000 |

| Model | 912D | 640D | 640D | 640D | 456D | 456D | 456D | 456D | 320D | 320D | 320D | 320D | 228D | 228D | 160D | 160D | 114D | 80D | |

| Gear Type | Double circular arc gear reducer or Involute gear reducer | ||||||||||||||||||

| Reducing Ratio | 28.79 | 28.363 | 28.363 | 28.363 | 28.255 | 28.255 | 28.255 | 28.255 | 28.807 | 28.807 | 28.807 | 28.807 | 28.873 | 28.873 | 28.506 | 28.506 | 28.355 | 31.832 | |

| Center Range (in) | 48.43 | 41.34 | 41.34 | 41.34 | 39.37 | 39.37 | 39.37 | 39.37 | 37.4 | 37.4 | 37.4 | 37.4 | 33.46 | 33.46 | 29.53 | 29.53 | 25.59 | 21.65 | |

| Center Height (in) | 30.91 | 25.98 | 25.98 | 25.98 | 25.59 | 25.59 | 25.59 | 25.59 | 23.23 | 23.23 | 23.23 | 23.23 | 19.69 | 19.69 | 17.72 | 17.72 | 16.73 | 13.78 | |

| Oil Storage quantity (U.S. Gal) | 180 | 106 | 106 | 106 | 100 | 100 | 100 | 100 | 75 | 75 | 75 | 75 | 42 | 42 | 27 | 27 | 25 | 12 | |

| Lubricant | 20# Gear lubricant in winter,200# Gear lubricant in summer | ||||||||||||||||||

| Sheave Diameter(in) | 50" | 50" | 50" | 50" | 44.4" | 44.4" | 44.4" | 44.4" | 44.4" | 44.4" | 44.4" | 44.4" | 36.4" | 36.4" | 30.4" | 30.4" | 30.4" | 24" | |

| Sheave groove type | 7C | 6C | 6C | 6C | 5C | 5C | 5C | 5C | 5C | 5C | 5C | 5C | 4C | 4C | 4C | 4C | 3C | 3C | |

| Balance Assembly | Weight of Cranks (Lbs) | 4482×2 | 3700×2 | 3700×2 | 3700×2 | 3630×2 | 3630×2 | 3630×2 | 3630×2 | 2996×2 | 2996×2 | 2996×2 | 2996×2 | 2160×2 | 2160×2 | 1553×2 | 1553×2 | 1553×2 | 896.5×2 |

| Wrist Pin bore Positions (in) | 47.09 | 47.09 | 47.09 | 47.09 | 47.05 | 47.05 | 47.05 | 47.05 | 42 | 42 | 42 | 42 | 42 | 42 | 32 | 32 | 32 | 24 | |

| 40.2 | 40.2 | 40.2 | 40.2 | 40.16 | 40.16 | 40.16 | 40.16 | 35.91 | 35.91 | 35.91 | 35.91 | 35.91 | 35.91 | 27 | 27 | 27 | 20 | ||

| 33.31 | 33.31 | 33.31 | 33.31 | 33.27 | 33.27 | 33.27 | 33.27 | 29.8 | 29.8 | 29.8 | 29.8 | 29.8 | 29.8 | 22 | 22 | 22 | 16 | ||

| Wire Line | Type | Φ32(6*37+IWR-1770 MPa) | Φ32(6*37+IWR-1770 MPa) | Φ32(6×37+IWR-1770 MPa) | Φ32(6×37+IWR-1770 MPa) | Φ32(6*37+IWR-1770 MPa) | Φ32(6×37+IWR-1770 MPa) | Φ32(6*37+IWR-1770 MPa) | Φ28(6×37IWR-1770MPa) | Φ28(6×37IWR-1770MPa) | Φ28(6×37IWR-1770MPa) | Φ28(6×37IWR-1770MPa) | Φ28(6×37IWR-1770MPa) | Φ28(6×37+IWR-1770 MPa) | Φ28(6×37+IWR-1770 MPa) | Φ28(6×37+IWR-1770 MPa) | Φ28(6×37+IWR-1770 MPa) | Φ28(6×37+IWR-1770 MPa) | Φ22(6×37+IWR-1770 MPa) |

| Length (in) | 445.98 | 445.98 | 400 | 445.98 | 360 | 445.98 | 400 | 400 | 360 | 360 | 360 | 360 | 295 | 330 | 260 | 295 | 260 | 193 | |

| Structure Unbalance (lbs) | -573 | -573 | 650 | -767 | 1937 | -754.5 | 234 | 5.4 | 362 | 362 | 1300 | 1276 | 2100 | 1154 | 882.2 | 2100 | 1173 | 90 | |

| Overall Dimensions L*W*H (in) | 482×113.7×355.1 | 474.18×138.58×353.74 | 444.1×107.6×344.2 | 470×109.4×355.2 | 421.9×109.4×334 | 470×109.4×355.2 | 440.16×109.37×344.3 | 440.16×109.37×344.3 | 409.53×125.6×301 | 409.53×125.6×301 | 384.84×125.6×292.6 | 384.84×125.6×292.6 | 339.1×89×270 | 335.6×89×282.8 | 284.45×83.9×216.3 | 273×83.9×250.5 | 273×78.4×212.2 | 214.3×60×167.6 | |

| Bearing Type | Wrist Pin | 22328C | 22328C | 22328C | 22328C | 22328C | 22328C | 22328C | 22328C | 22322C | 22322C | 22322C | 22322C | 22322C | 22322C | 22318C | 22318C | 22318C | 22314C |

| Tail Bearing | 22340CK | 22340C | 22340C | 22336C | 22340C | 22336C | 22336C | 22336C | 22330C | 22330C | 22330C | 22330C | 22330C | 22330C | 22326C | 22326C | 22326C | 22318C | |

| Center Bearing | NJ240 | NJ240 | NJ240 | NJ2334 | NJ240 | NJ2334 | NJ2334 | NJ2334 | NJ2330E | NJ2330E | NJ2330E | NJ2330E | NJ2330E | NJ2330E | NJ228 | NJ228 | NJ228 | NJ220E | |

| Sealing Ring | Wrist Pin | 130×160×12 | 130×160×12 | 130×160×12 | 130×160×12 | 130×160×12 | 130×160×12 | 130×160×12 | 130×160×12 | 110×140×12 | 110×140×12 | 110×140×12 | 110×140×12 | 110×140×12 | 110×140×12 | 90×120×12 | 90×120×12 | 90×120×12 | 70×95×10 |

| Tail Bearing | 190×220×15 | 190×220×15 | 190×220×15 | 160×190×15 | 190×220×15 | 160×190×15 | 160×190×15 | 160×190×15 | 140×170×15 | 140×170×15 | 140×170×15 | 140×170×15 | 140×170×15 | 140×170×15 | 120×150×12 | 120×150×12 | 120×150×12 | 70×95×10 | |

| Center Bearing | 200×230×15 | 200×230×15 | 200×230×15 | 170*200*15 | 200×230×15 | 170×200×15 | 170×200×15 | 170×200×15 | 150×180×15 | 150×180×15 | 150×180×15 | 150×180×15 | 150×180×15 | 150×180×15 | 140×170×15 | 140×170×15 | 140×170×15 | 100×125×12 | |

| Reducer Bearing | Output Shaft | Bearing 22244CA | Bearing 22244CA | Bearing 22244CA | Bearing 22244CA | Bearing 22244CA | Bearing 22244CA | Bearing 22244CA | Bearing 22244CA | Bearing 22238CA | Bearing 22238CA | Bearing 22238CA | Bearing 22238CA | Bearing 23136CA | Bearing 23136CA | ||||

| Intermediate Shaft | Bearing NU2330E | Bearing NU2326 | Bearing NU2326 | Bearing NU2326 | Bearing NU2326M | Bearing NU2326M | Bearing NU2326M | Bearing NU2326M | Bearing NU2224E | Bearing NU2224E | Bearing NU2224E | Bearing NU2224E | Bearing NU2322E | Bearing NU2322E | |||||

| High Speed Shaft | Bearing NU2324E | Bearing NU2322M | Bearing NU2322M | Bearing NU2322M | Bearing NU2322M | Bearing NU2322M | Bearing NU2322M | Bearing NU2322M | Bearing NU2320E | Bearing NU2320E | Bearing NU2320E | Bearing NU2320E | Bearing NU2217E | Bearing NU2217E | |||||

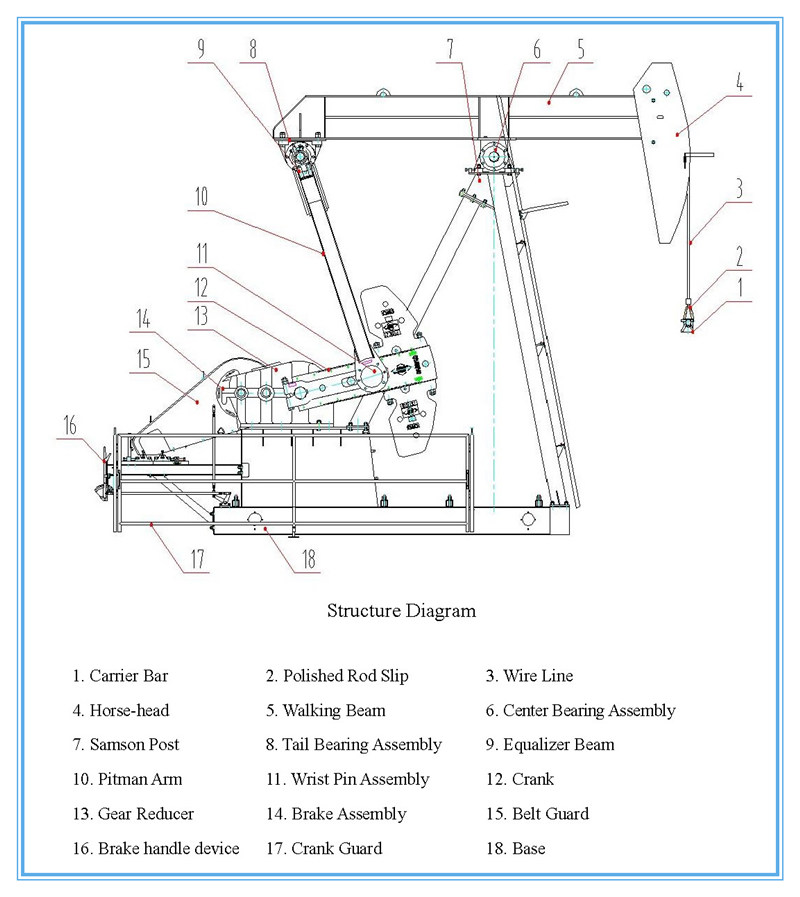

Main Parts and Details

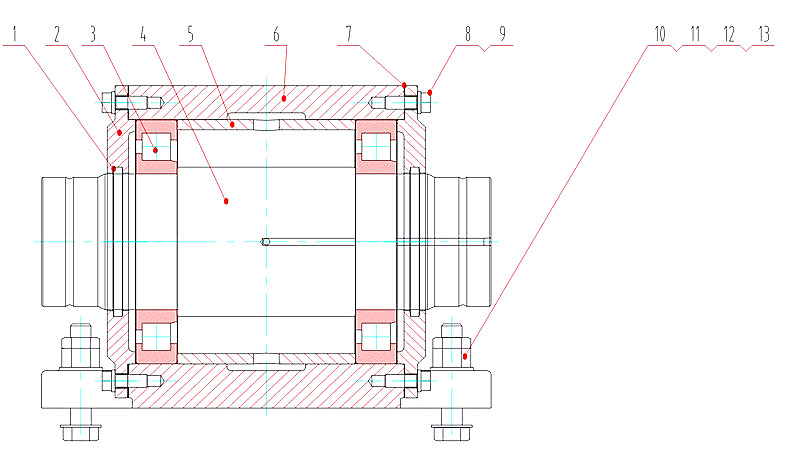

1) Center Bearing Assembly

| No. | Name | Qty. | Remark |

| 1 | Seal ring | 2 |

|

| 2 | Bearing cover | 2 |

|

| 3 | Bearing | 2 |

|

| 4 | Center bearing | 1 |

|

| 5 | Space ring | 1 |

|

| 6 | housing | 1 |

|

| 7 | washer | 2 |

|

| 8 | bolt | 12 |

|

| 9 | Spring washer | 12 |

|

| 10 | bolt | 4 |

|

| 11 | Thin nut | 4 |

|

| 12 | nut | 4 |

|

| 13 | washer | 4 |

|

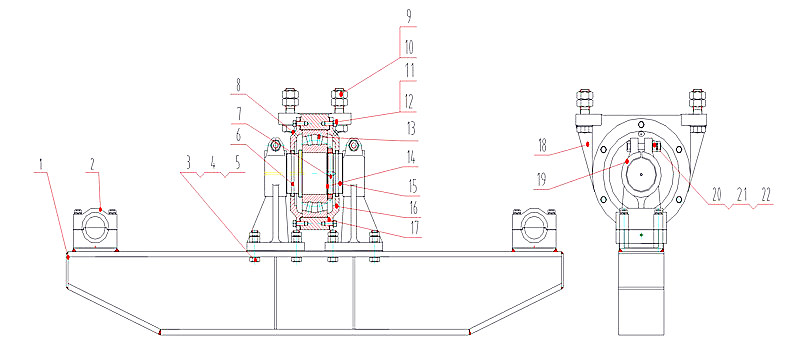

2).Equalizer Bearing Assembly

| No. | Name | Qty. | Remark |

| 1 | Equalizer | 1 |

|

| 2 | hanger | 2 |

|

| 3 | Hexagon bolt | 8 |

|

| 4 | nut | 8 |

|

| 5 | Thin nut | 8 |

|

| 6 | Oil seal | 2 |

|

| 7 | Round nut | 1 |

|

| 8 | Grease fitting | 2 |

|

| 9 | Hexagon bolt | 4 |

|

| 10 | Hexagon nut | 8 |

|

| 11 | Hexagon bolt | 12 |

|

| 12 | Spring washer | 12 |

|

| 13 | Self-aligning roller bearing | 1 |

|

| 14 | Stop washer | 1 |

|

| 15 | Tail bearing | 1 |

|

| 16 | Bearing cover | 2 |

|

| 17 | 2 |

| |

| 18 | housing | 1 |

|

| 19 | Equalizer bearing | 2 |

|

| 20 | Hexagon bolt | 2 |

|

| 21 | Hexagon nut | 2 |

|

| 22 | Hexagon thin nut | 2 |

|

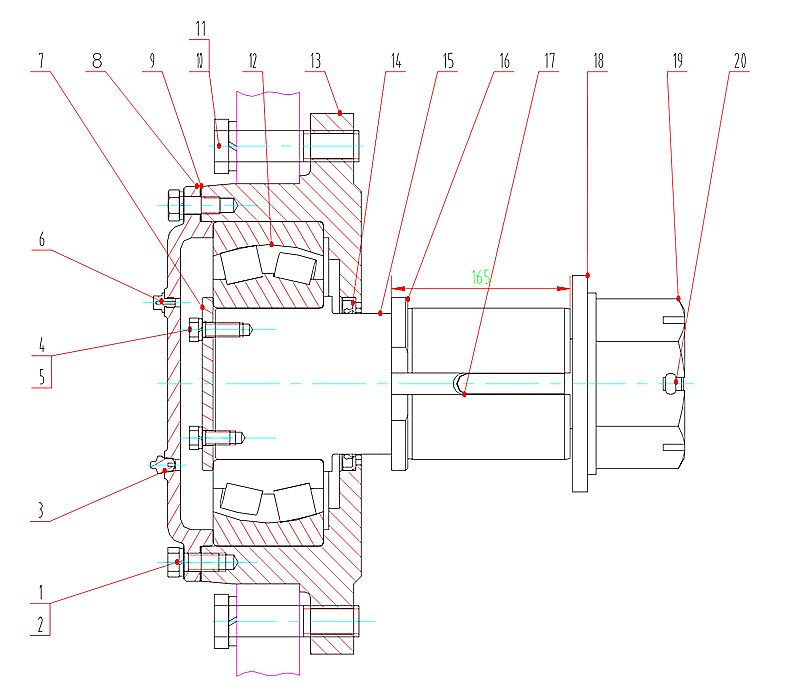

3).Crank Pin Assembly

| No. | Name | Qty. | Remark |

| 1 | bolt | 6 |

|

| 2 | Spring washer | 6 |

|

| 3 | Grease fitting | 1 |

|

| 4 | bolt | 2 |

|

| 5 | Spring washer | 2 |

|

| 6 | Relief screw | 1 |

|

| 7 | Bearing cover plate | 1 |

|

| 8 | Bearing cover | 1 |

|

| 9 | washer | 1 |

|

| 10 | Bolt | 4 |

|

| 11 | Spring washer | 4 |

|

| 12 | Bearing | 1 |

|

| 13 | Pitman bearing | 1 |

|

| 14 | Oil seal | 1 |

|

| 15 | Crank pin | 1 |

|

| 16 | sleeve | 1 |

|

| 17 | key | 1 |

|

| 18 | Retainer ring | 1 |

|

| 19 | nut | 1 |

|

| 20 | Cotter pin | 1 |

|

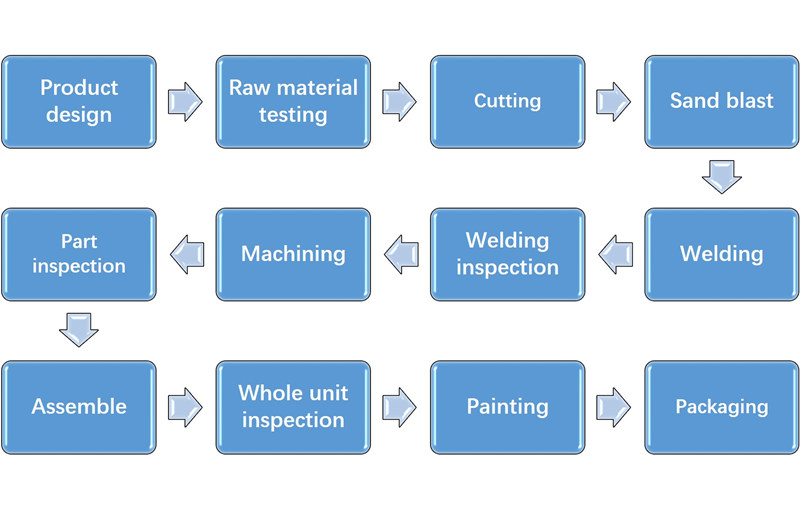

SANJAC produces the pumping unit according to the following process flow:

Shengji Petroleum Pumping Unit Manufacturing Plant is one of the main branches of Shengji Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales and service of pumping units. The factory has 235 employees, more than 130 sets of various large and medium-sized mechanical processing equipment, fixed assets of 12 million yuan, annual output of 1,200 pumping units, and annual sales income of 200 million yuan.

There are 4 senior engineers, 12 intermediate engineers, 7 assistant engineers, 4 senior technicians and 12 technicians in the pumping unit. Intermediate and senior workers account for more than 90% of all workers. The superb technical level of employees provides a technical guarantee for the production of high-quality pumping units.